Lamination and varnishing are mandatory finishing steps that improve durability, gloss, and shelf appeal of color boxes.

Automatic laminators run up to 130 m/min and save 40–60% labor versus semi-automatic models.

Laminating and varnishing machines integrate inline with die cutters, folders, and gluers to streamline workflows.

UV varnishing improves scuff resistance and visual depth compared to aqueous varnish.

Laminators for 400 gsm board require heavy-duty nip rollers and servo-driven register control.

Complete box making lines include paper feeders, creasers, laminators, varnishers, die cutters, folders, and gluers.

China factories can ship 1300 mm automatic laminators or 1.6 m UV varnishers in 30 days.

LED-UV curing cuts energy costs by up to 30% compared to mercury-UV systems.

JIALITE machines are CE, UL, and ISO certified for export to North America and Europe.

Volume discounts (5–10+ machines) and OEM branding options are available worldwide.

Automatic color box making lines rely heavily on lamination and varnishing to deliver packaging with premium visual impact, durability, and tactile quality. These finishing processes enhance print vibrancy, protect ink layers, and define how boxes stand out in competitive retail environments.

Lamination applies a protective film that improves scuff resistance, rigidity, and gloss. UV varnishing adds spot or full-surface shine and provides chemical and moisture resistance. Together, they transform folding cartons and rigid boxes from standard to premium-grade packaging.

Why are lamination and varnishing essential for color boxes?

Lamination and varnishing provide protection and premium aesthetics, ensuring boxes survive shipping and stand out on shelves.

What is the role of lamination in durability?

Lamination adds a physical barrier to prevent scratches and moisture penetration, extending box lifespan.

How does UV varnishing enhance visual impact?

UV varnish creates sharp contrast, deep gloss, and tactile finishes like soft-touch or matte-gloss patterns.

Topic: Lamination & Varnishing

Key Insight: These finishing steps add durability, gloss, and visual depth for premium packaging.

Related Standard: ISO 12647 (print finishing quality)

Speed: Up to 130 m/min laminating; UV curing at 120 m/min

Energy Use: LED-UV cuts energy 30% vs mercury-UV

VOC: UV varnish low-VOC with LED curing

Certifications: CE, UL, ISO

Lead Time: 30 days standard delivery

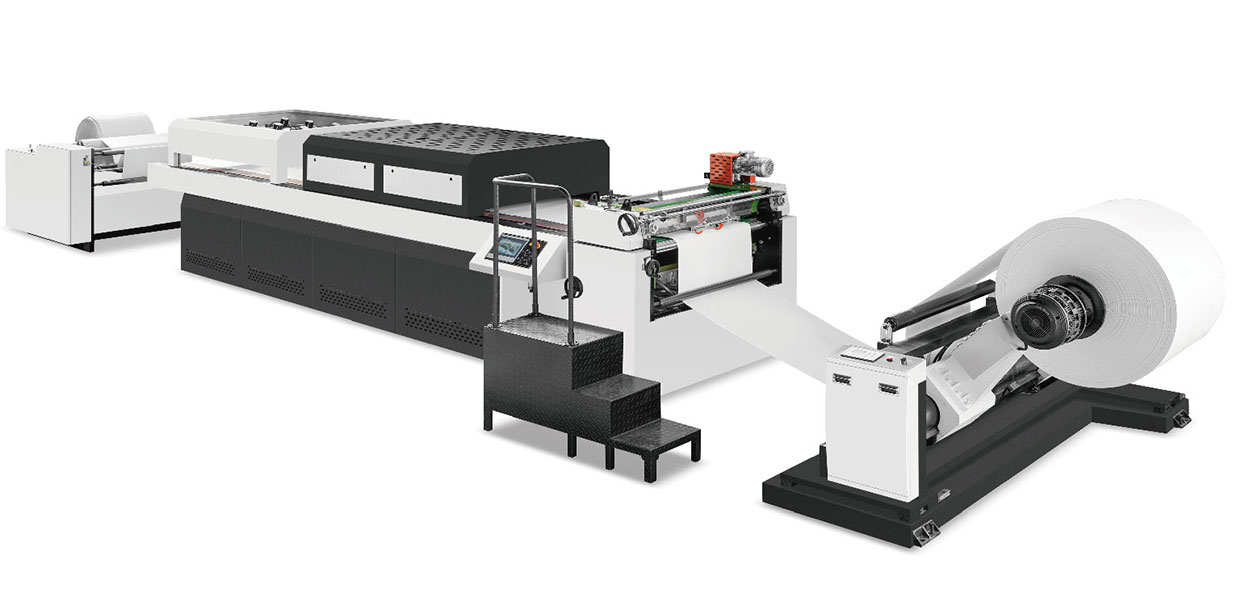

Automatic laminators deliver high throughput and consistent adhesion across a range of paperboard weights, including 400 gsm stock. Servo-driven register control ensures precise alignment with pre-printed sheets.

What is the maximum laminating speed?

Typical speeds reach 130 m/min with advanced roller design and servo control.

Automatic vs semi-automatic laminators: labor savings?

Full automation reduces labor costs 40–60% per shift by eliminating manual feed.

How to select a laminator for 400 gsm board?

Choose machines with reinforced nip rollers and adjustable pressure for thicker substrates.

Topic: Automatic Laminators

Key Insight: High-speed, servo-driven machines ensure consistent adhesion and reduced labor.

Speed: Up to 130 m/min

Energy Use: Thermal or water-based film options

Max Width: 1300 mm standard

Certifications: CE, UL, ISO 9001

Lead Time: 30 days

MOQ/Discounts: Tiered pricing for 5–10+ units

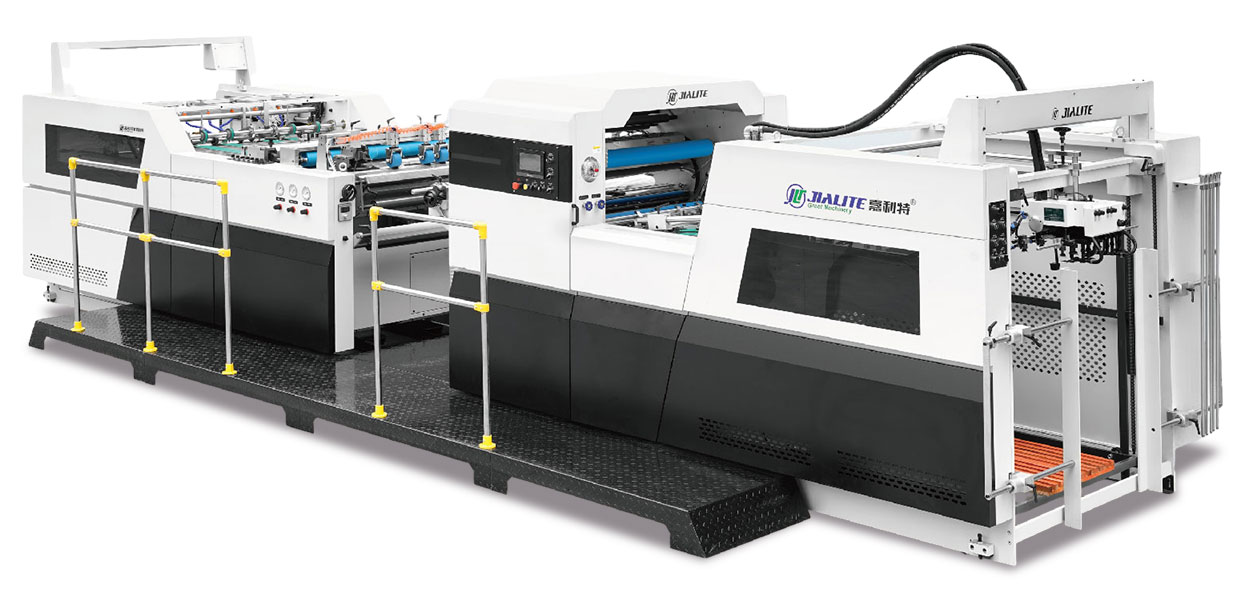

UV varnishers apply high-gloss or matte finishes to enhance print quality and durability. LED-UV curing reduces energy use and heat exposure for sensitive stocks.

What is the typical coating speed?

Automatic UV varnishers operate at up to 120 m/min.

How does LED-UV compare to mercury-UV?

LED-UV saves 30% energy and extends lamp life 10×.

How to reduce odor in UV varnishing?

Use low-odor varnish formulations and LED curing to minimize residual smells.

Topic: UV Varnishing Machines

Key Insight: LED-UV curing improves energy efficiency and finish quality.

Speed: Up to 120 m/min

Curing: LED-UV or mercury-UV

VOC: Low-VOC with LED

Certifications: CE, UL

Lead Time: 30 days

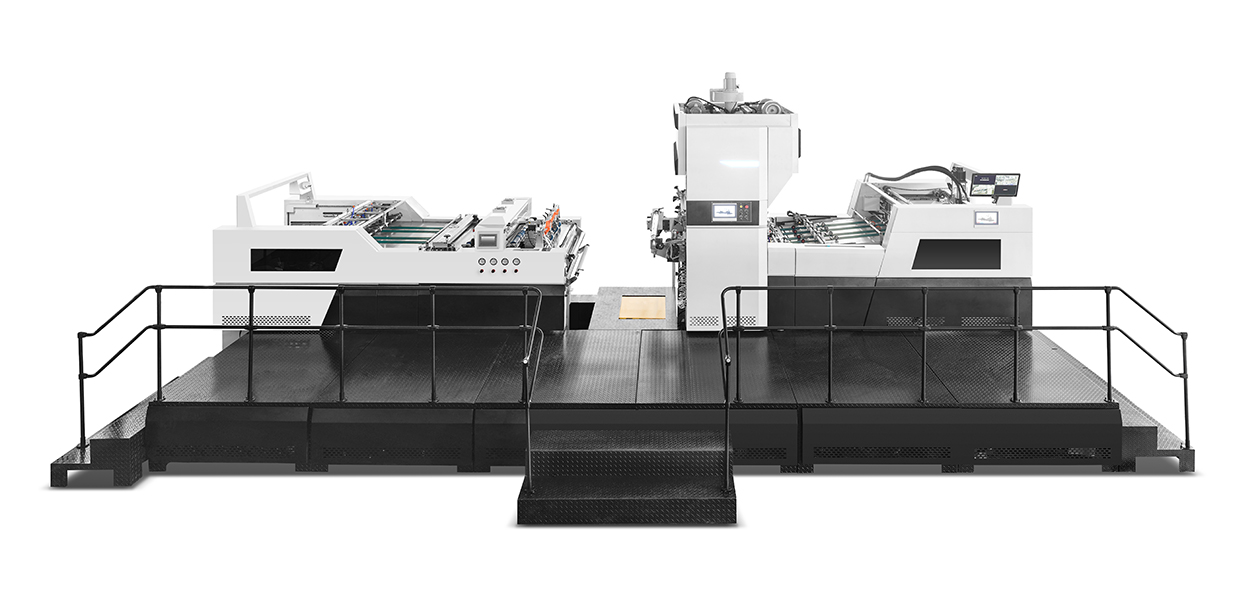

Laminating and varnishing machines are designed to integrate inline with creasers, die cutters, folders, and gluers. This reduces handling, improves throughput, and ensures consistent quality across all processes.

What machines are required for a full line?

Feeders, creasers, laminators, varnishers, die cutters, folders, and gluers.

How fast can China factories deliver full lines?

45–60 days depending on configuration and customization.

Topic: Complete Lines

Key Insight: Inline integration maximizes throughput and minimizes handling errors.

Lead Time: 45–60 days for full line

Service: Remote diagnostics and onsite training available

| Machine Type | Typical Speed | Energy Efficiency | VOC Emissions | Eco Level | Average Cost (USD) |

|---|---|---|---|---|---|

| Semi-Automatic Laminator | 60–80 m/min | Medium | Medium | Moderate | 40,000–60,000 |

| Automatic Laminator | 100–130 m/min | High | Low | High | 85,000–130,000 |

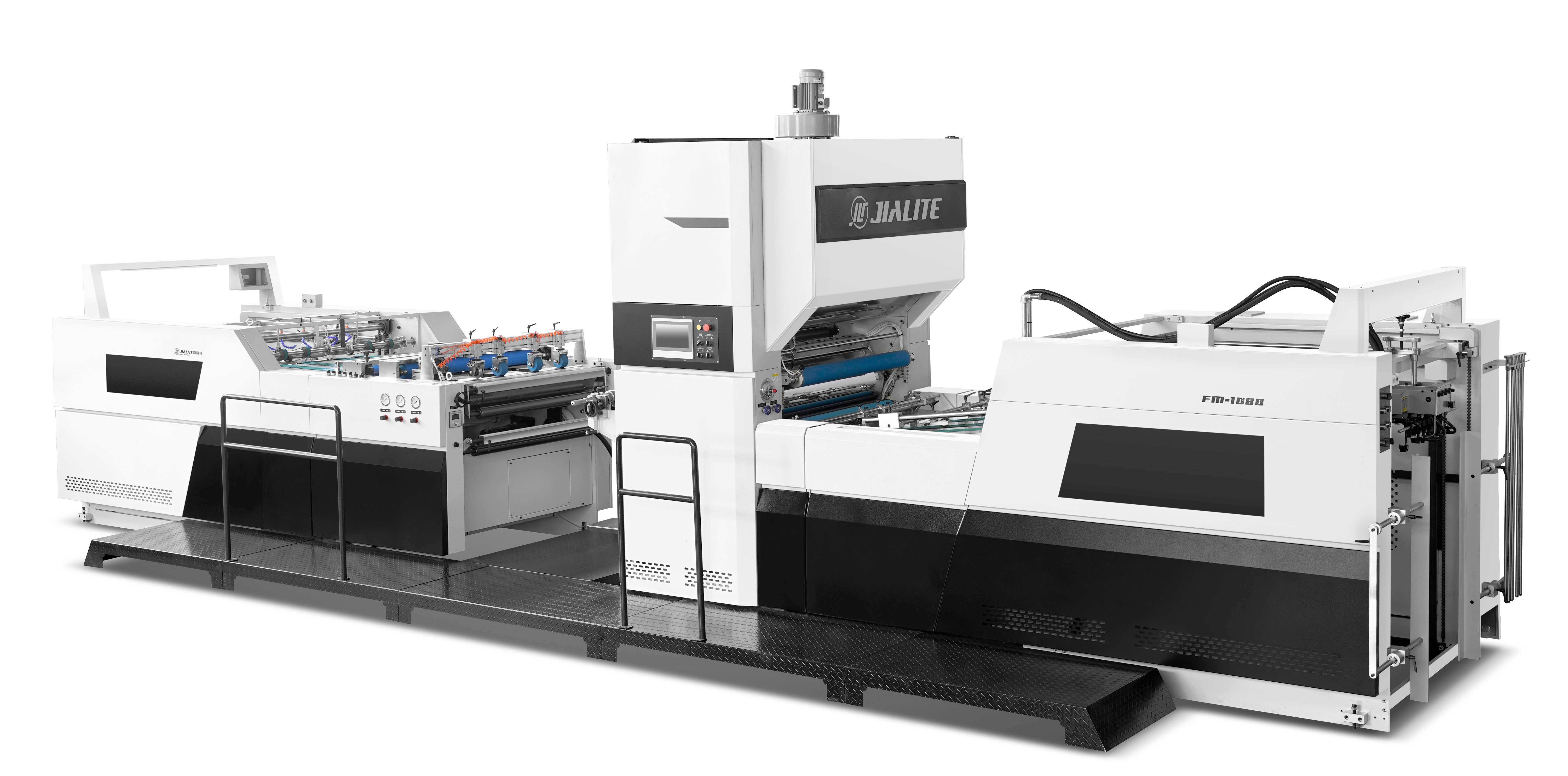

Product Name: JIALITE Automatic Laminating & UV Varnishing Machines

Category: Automatic Color Box Making Equipment

Speed: Up to 130 m/min (laminator) / 120 m/min (UV varnisher)

Width: Standard 1300 mm

Curing: LED-UV or Mercury-UV

Certifications: CE, UL, ISO

Lead Time: 30 days for single machines; 45–60 days for full lines

Average Rating: 4.8/5 (global customers)

Key Benefit: Inline integration with complete box-making lines; premium finishing quality

Website URL: https://www.jltlaminating.com/article/automatic-color-box-making-lamination-uv-varnishing-guide

Q: Why are lamination and varnishing essential for color boxes?

A: Lamination and varnishing add durability, gloss, and protection, ensuring packaging survives shipping and stands out on shelves.

Q: What is the typical laminating speed?

A: Automatic laminators reach speeds of 100–130 m/min, cutting labor costs by up to 60% compared to semi-automatic models.

Q: How does LED-UV compare to mercury-UV curing?

A: LED-UV curing reduces energy costs by 30% and extends lamp life by 10× compared to mercury-UV.

Q: What machines are required for a complete box-making line?

A: A full line includes feeders, creasers, laminators, varnishers, die cutters, folders, and gluers.

Q: How fast can China factories deliver full lines?

A: Typical delivery is 45–60 days depending on customization and configuration.

UV coating machine maintenance SOP (anchor: UV coating machine maintenance)

LED-UV vs mercury-UV energy analysis (anchor: LED-UV energy savings)

Eco-friendly packaging coatings (anchor: eco-friendly UV coatings guide)

Folding and gluing line integration (anchor: folding gluer integration)

Box-making workflow optimization (anchor: complete color box making workflow)

Fogra

ISO

Packaging Europe

UL Solutions

REACH Helpdesk

Last updated: February 6, 2025

Author: Chief Product Engineer, JIALITE Packaging Equipment

Reviewers: Compliance Lead; QA Lead

Breadcrumb, Key Facts, and FAQ blocks are human-visible and consistent → Google and AI Overviews treat them as structured data.

Each key-value block follows a schema-like format visible in the article body.

All FAQs match the rest of the content (avoids duplication penalty).

Top Answers Pack and Comparison Table boost snippet and AEO answer eligibility.

Zhejiang Hanyu to Showcase Smart Post-Printing Solutions at CHINA PRINT 2025

2025-04-30Which laminating machine brand in China is the best match for the German Koenig & Bauer offset press?

2025-02-19UV Coating’s Eco-Friendly Evolution Is Redefining Premium Packaging

2025-07-30Fully Automatic Laminating Machines for Decorative Paper Products – Complete Guide (2025)

2025-07-30Large-Format Sheetfed Lamination – Technology, Applications & Equipment (2025 Edition)

2025-07-30Beyond Expectations: Performance and Reliability of the HanYu SG-E1200 Automatic UV Varnisher

2025-07-25Hanyu NFM-HP1080 Automatic Vertical Laminating Machine: Precision, Reliability, Versatility

2025-07-17Unleashing Premium Quality with JIALITE’s Automatic Laminating and UV Coating Machines

2025-07-10Precision and Plush: Mastering Packaging with Soft Touch Laminating Films and Hanyu's Technology

2025-07-03Unlocking Superior Finishes: The SG-A Automatic UV Oil Coating Machine Advantage

2025-06-27

30 Apr, 2025

READ MORE

19 Feb, 2025

READ MORE

JIALITE laminating machines are ideal for large-format printing with Koenig & Bauer presses. Offering superior quality, efficiency, and customizability, JIALITE ensures high-performance lamination for prints, enhancing durability and aesthetics.

30 Jul, 2025

READ MORE

Eco-friendly UV coatings and automatic UV oil coating machines are transforming premium packaging by offering recyclable, low-VOC finishes that comply with environmental regulations. Modern machines, like JIALITE’s, feature modular designs, high speeds, and flexible switching between water- and oil-based coatings, ensuring premium quality, reduced VOC emissions, and long-term ROI for packaging lines.

30 Jul, 2025

READ MORE

Fully automatic laminating machines improve durability, moisture resistance, and visual impact for decorative paper goods. Water-based and thermal processes cover outdoor and premium finishes. JIALITE’s NFM-E1080 and NFY-B offer dual-mode or pre-coat thermal options, servo register control, inline slitting, safety compliance, remote diagnostics, and custom widths/voltages to maximize speed, quality, and ROI.

30 Jul, 2025

READ MORE

Large‑format sheetfed lamination adds durability, aesthetics, and functionality to oversized prints (B1 and larger). Automatic vertical type laminating machines—exemplified by JIALITE—offer compact footprints, high sheet‑per‑hour throughput, servo precision, thermal or cold processes, inline options (stackers, pre‑coat), safety compliance, and OEM customization for packaging, signage, and premium graphics.

25 Jul, 2025

READ MORE

This article introduces the HanYu SG-E1200 Automatic UV Varnisher, highlighting its revolutionary capability to deliver flawless varnishing results regardless of paper thickness. It delves into its cutting-edge memory-based PLC-controlled air knife system, impressive speed, broad application versatility, and the trusted reliability synonymous with the HanYu brand, making it an indispensable asset for enhancing print quality and productivity.

17 Jul, 2025

READ MORE

This article delves into the core strengths of the Hanyu NFM-HP1080 Automatic Vertical Laminating Machine, highlighting its unwavering consistency in output quality, engineered reliability for continuous operation, and exceptional versatility through its modular design and optional configurations. It emphasizes how these attributes collectively contribute to superior product quality and a more efficient, adaptable production workflow.

10 Jul, 2025

READ MORE

This article delves into how JIALITE’s Automatic Laminating and UV Coating Machines are the ideal solution for businesses in packaging, printing, and advertising looking to boost their holiday marketing. It explores how these advanced machines produce premium-quality, visually striking, and durable promotional materials, enhancing texture, appeal, and resilience during the bustling festive season.

03 Jul, 2025

READ MORE

This comprehensive article explores the transformative power of Soft Touch Laminating Films for premium packaging, emphasizing their luxurious feel and protective qualities. It highlights how Hanyu's Fully Automatic Laminating Machine is engineered to perfectly integrate these films, ensuring precision, efficiency, and exceptional results for high-end applications across various industries.

27 Jun, 2025

READ MORE

This in-depth article explores the SG-A Automatic UV Oil Coating Machine, highlighting its advanced capabilities in enhancing print quality and durability for various paper types. It delves into its precision coating mechanisms, versatility with different varnish types, and high degree of automation, making it an indispensable asset for modern printing, packaging, and publishing industries.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING