AUTOMATIC VERTICAL LAMINATING MACHINE 2 IN 1

AUTOMATIC THERMAL LAMINATING MACHINE

AUTOMATIC UV OIL COATING MACHINE

CONSUMABLE MATERIAL

ROLL TO ROLL WATERBASE OIL COATING MACHINE

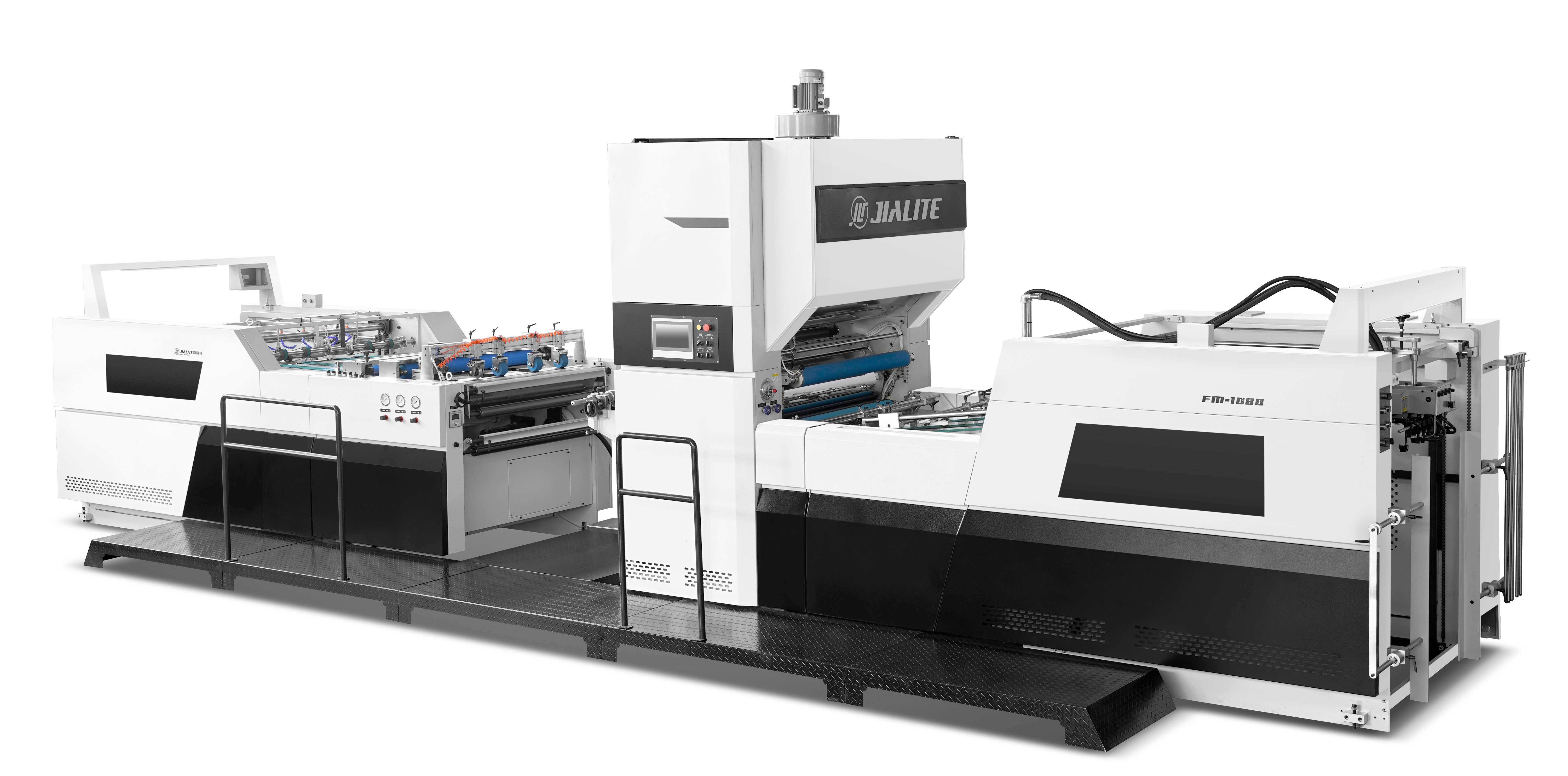

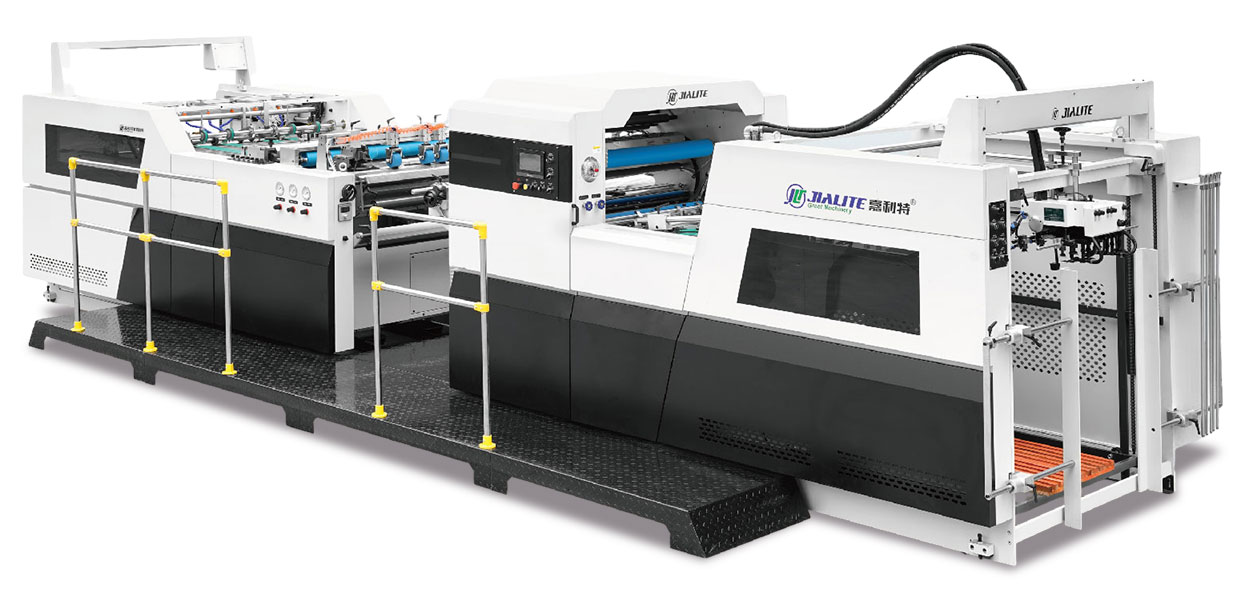

The NFM-E1080 High-Speed Automatic Vertical Laminating Machine is designed with advanced features like the Hot Knife, Window Unit, and Single Embossing Unit, ensuring precision lamination for various film materials. This versatile machine is ideal for large-scale production, delivering exceptional results in lamination, cutting, and embossing.

The NFM-E1080 Automatic Vertical Laminating Machine with Chain Knife offers high-speed, precise lamination for various materials, including BOPP, OPP, PET, PLA, PP, and metal films. This automatic vertical laminating machine provides superior performance for businesses seeking reliable lamination solutions in China.

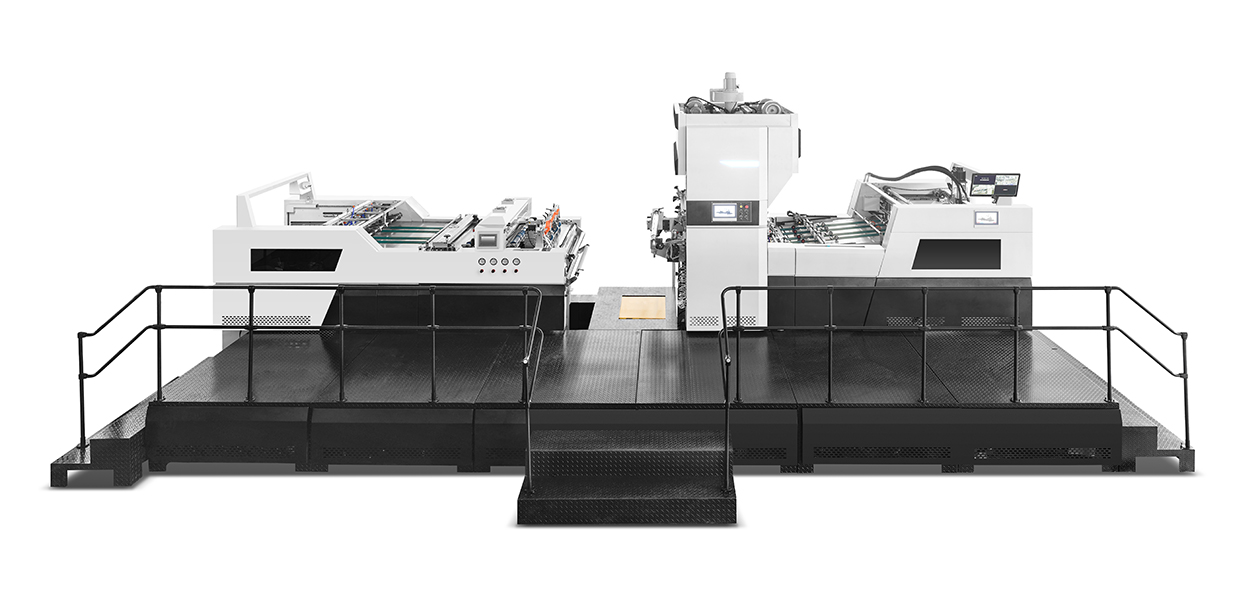

NFM-HP Fully automatic conveying vertical High-precision and multi-duty laminating machine as a professional equipment used for plastic film laminating on the surface of paper printed matter, This machine was first published on the 10th Beijing International Printing and technology with mine exhibition conveying device, front can be connected to printing machine, rear can be connected to automatic die-cutting machine.

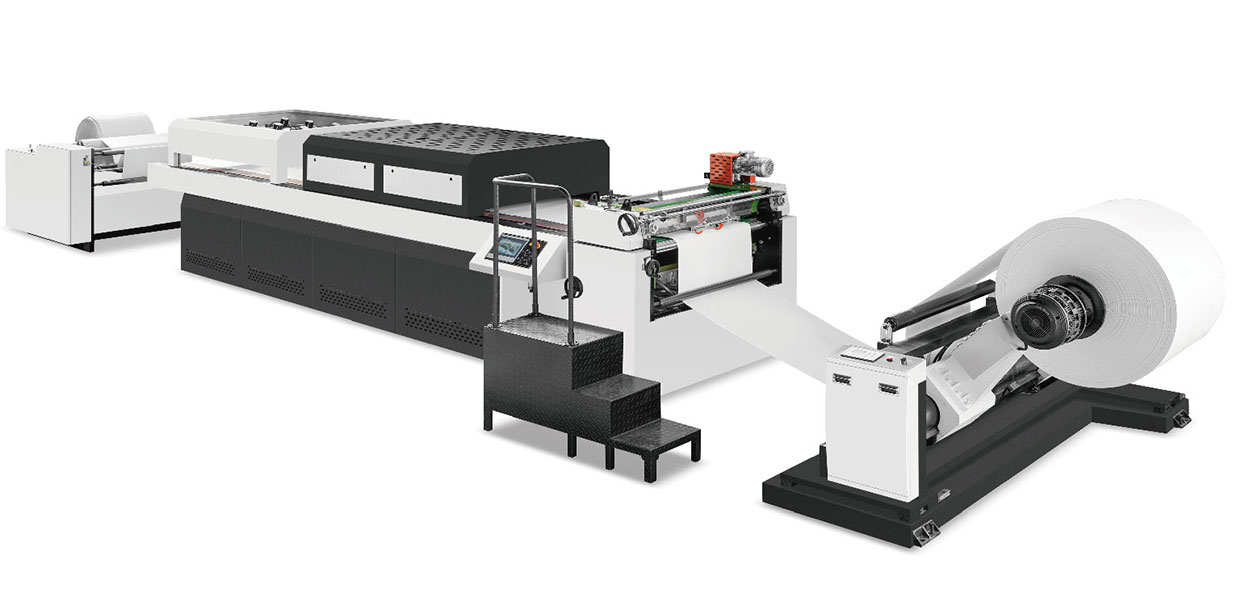

As a reputable manufacturer of printing and packaging machinery, we're excited to introduce the SG-AR1200 Automatic Roll to Roll UV Oil Varnish Coating Machine. This cutting-edge equipment is engineered to enhance the quality and protection of your printed materials, offering precision and efficiency for a variety of applications.

As a leading manufacturer of printing and packaging machinery, we proudly introduce our SG-II-1200/1500/1700/1900 Automatic Double Coaters and Double Dryer Channel Oil Coating Machine. This state-of-the-art equipment is designed to elevate your printing and coating processes, offering precision, efficiency, and versatility to meet the demands of diverse industries.

The SG-II series is ideal for precise and consistent oil coating on various materials, enhancing their visual appeal, durability, and protection. These machines are well-suited for industries such as printing, packaging, and publishing, where high-quality coatings are essential to make your products stand out in the market.

As a leading manufacturer of printing and packaging machinery, we're delighted to present the SG-A Automatic UV Oil Coating Machine. This state-of-the-art equipment is designed to enhance the quality and protection of your printed materials, offering precision and efficiency for a wide range of applications.

The SG-A Automatic UV Oil Coating Machine is tailored for precise and consistent UV oil coating, improving the vibrancy and durability of your prints. It's an excellent choice for industries such as printing, packaging, and publishing, where high-quality coatings are essential to elevate the visual appeal and longevity of printed materials.

NFM-H proudly presents the SG-E series, featuring the SG-E1200, SG-E1500, SG-E1700, and SG-E1900 Automatic UV Oil Coating Machines. These cutting-edge machines are engineered to elevate UV oil coating processes across various industries. With advanced technology and user-friendly features, they offer a reliable and efficient solution for enhancing the finish and protection of your printed materials.

Elevate your thermal film laminating processes with the NFY-B Automatic Thermal Film Laminating Machine by NFM-H. This versatile machine ensures precise and consistent lamination results for a professional finish on various materials. Ideal for industries like printing, packaging, and publishing, it offers user-friendly controls, advanced heat management, and built-in safety features. Boost your productivity with this efficient and reliable laminator. Customize it to meet your unique requirements and enjoy cost-effective and high-quality laminating solutions. Choose NFM-H for superior thermal film laminating results.

NFM-H is proud to present the NFY-A800 High Speed Thermal Laminator, a cutting-edge solution designed to revolutionize the thermal laminating process for industries around the world. This advanced machine combines state-of-the-art technology with user-friendly features, offering a reliable and high-speed solution for thermal laminating applications.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING