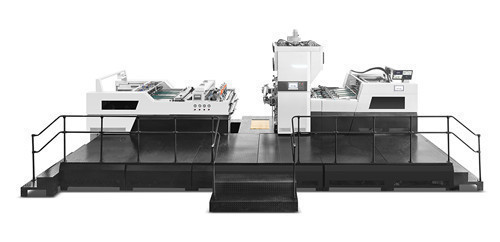

The quality of work produced by a roll to roll lamination machine is top-notch, making it a popular choice in various industries. The machine is designed to laminate materials, such as fabrics, paper, and film, to provide protection, durability, and improved aesthetic appearance.

The lamination process involves feeding the target material through the machine, where it is coated on both sides with a layer of protective film. The coated material is then rolled onto a spindle, where it can be easily transported, stored or further processed.

Thanks to its high-speed and precision, a roll to roll lamination machine ensures that the coated material is uniformly coated and without any bubbles, wrinkles, or ripples. The result is a smooth and professional-looking finish that enhances the quality and durability of the target material.

Moreover, the lamination process itself offers several benefits, such as protecting the material from moisture, environmental damage, and wear and tear. In addition, it can add a glossy, matte or textured finish that can make the material more appealing to the eye.

Overall, the quality of work produced by a roll to roll lamination machine is unparalleled, making it a reliable and cost-effective solution for various industries, including packaging, textile, printing, and more.

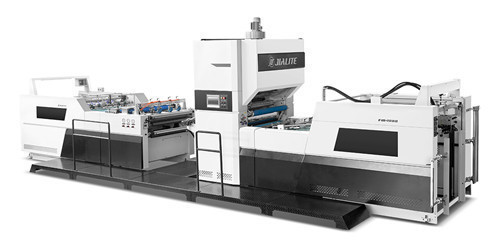

The roll to roll lamination machine is highly efficient and can significantly improve the productivity of your lamination process. With its advanced features and cutting-edge technology, this machine can laminate large volumes of materials quickly and accurately.

The machine's automated system eliminates the need for manual feeding and helps to save time and labor costs. Moreover, the adjustable speed control allows you to customize the lamination process according to your specific needs and requirements.

The user-friendly interface and easy-to-operate controls make it easy for anyone to use the roll to roll lamination machine. The machine is also designed to be highly durable and requires very little maintenance, making it a cost-effective choice for your business.

In summary, if you are looking for a highly efficient and reliable lamination solution, the roll to roll lamination machine is an excellent choice. Its advanced features, ease of use, and low maintenance requirements make it a valuable addition to any workspace.

The roll to roll lamination machine is incredibly easy to use. With its user-friendly interface and intuitive controls, anyone can operate it with ease. Its simple touch screen display allows for effortless navigation through its various settings and functions. Plus, its compact design ensures that it can fit easily into any workspace, making it a great option for businesses of all sizes. Whether you're a small shop or a large corporation, this machine offers unparalleled convenience and usability. So if you're looking for a reliable and easy-to-use lamination solution, look no further than the roll to roll lamination machine.

The roll to roll lamination machine is incredibly user-friendly and intuitive to use. With its streamlined design and intuitive controls, it's easy for anyone to operate, no matter their level of experience.

Thanks to its simple and straightforward interface, users can quickly master the process of loading materials, setting temperatures, and adjusting the speed of the machine to achieve the perfect lamination results.

Additionally, the machine's high level of automation helps to minimize the time and effort required to run it. With features like automatic tension control and material alignment sensors, the machine practically takes care of itself, allowing users to focus on other tasks while it runs in the background.

Overall, the roll to roll lamination machine is an incredibly user-friendly tool that's ideal for businesses of all sizes. Whether you're a seasoned professional or just getting started in the world of lamination, you'll find that this machine is intuitive, efficient, and easy to use.

Roll to roll lamination machines are an essential asset for businesses that need to create high-quality laminated products such as labels, posters, and packaging materials. The cost of a roll to roll lamination machine can range from $3,000 to $20,000 depending on the features, size, and brand.

The price of the machine is influenced by several factors such as the type of film used, the speed of the machine, and the size of the rolls it can handle. It is important to note that investing in a high-quality and durable roll to roll lamination machine can help businesses save money in the long run by reducing maintenance costs and increasing productivity.

Overall, the cost and price of a roll to roll lamination machine may seem daunting at first, but the benefits and long-term savings make it a worthwhile investment for businesses that require high-quality lamination.

GREAT since from 1995. Continuous introduction the European concept of equipment manufacturing, based on more than 20 years experience, we focus on the development and innovation of laminating machine and UV coating machine, GREAT provide efficiency products and reasonable post press solution to every user.

Company structure is scientific and reasonable with humanized management mechanism. The ERP management system and 5S standard are used to ensure the strict system of development,procurement, processing, production and assembly, factory inspection, packaging and logistics.Mature customer service system, the domestic First-tier and second-tier cities have direct selling and service branch, technical engineers team at any time provide after-sale consultation and arrangement installation and troubleshooting service for foreign customers.

Daily maintenance of coating machine

2022-02-24Care and maintenance of coating machine

2022-02-21Application field of automatic coating machine

2022-01-21How to choose Automatic coating machine manufacturers

2022-01-1824 Feb, 2022

READ MORE

The transmission and moving parts of the newly installed coating machine must be inspected, tightened, refueled and maintained within a week of use; after that, regular inspection and maintenance must be carried out every month.

21 Feb, 2022

READ MORE

Ensure that the coating equipment is installed horizontally. It should be grounded, and an independent leakage switch should be installed for safe use.

21 Jan, 2022

READ MORE

Liquid ink manufacturing for testing ink shade/strength and coatings.

18 Jan, 2022

READ MORE

Due to the lack of in-depth understanding, most friends do not know which part of Automatic coating machine manufacturers to choose to obtain satisfactory results. In fact, as long as we have the patience to explore more things, we will soon know that manufacturers that have been established for many years, while focusing on the industry, have cooperated with different customers, and they will definitely have strong strength.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING