Products

Products

AUTOMATIC VERTICAL LAMINATING MACHINE 2 IN 1

AUTOMATIC VERTICAL LAMINATING MACHINE 2 IN 1

NFM-H1080W Automatic Vertical Window Laminating Machine with Hot Knife

NFM-H1080W Automatic Vertical Window Laminating Machine with Hot Knife

NFM-H1080W Automatic laminating machine with window patching unit,ease of peration with Intelligent automation, labor liberation,Internet of things remote auxiliary control system, data generation and management to create perfect conditions for sustainable production.Are you looking for a reliable, efficient and cost-effective way to laminate your vertical windows? Then the Automatic Vertical Window Laminating Machine with Hot Knife Technology is the perfect solution for you. This machine is designed to provide exceptional performance and maximum efficiency in the lamination process.

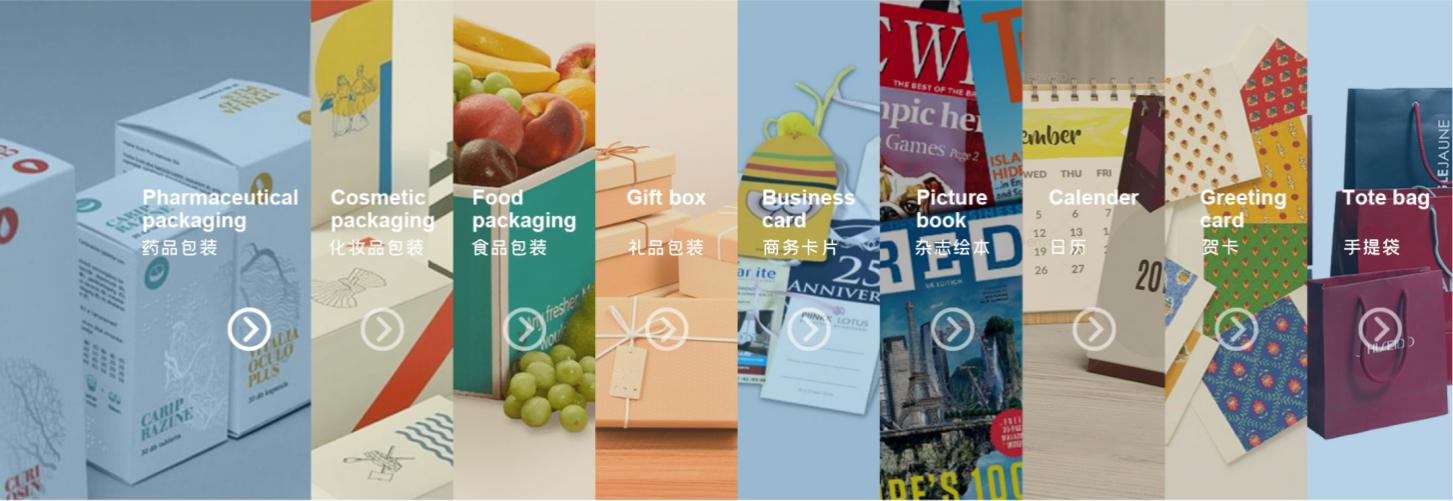

Application

NFM-H1080W Automatic laminating machine with window patching unit,ease of peration with Intelligent automation, labor liberation,Internet of things remote auxiliary control system, data generation and management to create perfect conditions for sustainable production.The Automatic Vertical Window Laminating Machine with Hot Knife is the perfect solution for companies looking to quickly and efficiently laminate their windows with a professional finish. This machine is designed to make lamination easy, with its patented hot knife technology that can easily cut heavy-through duty vinyl film, PVC foil and other materials. It also has an adjustable speed control that allows you to set the lamination speed according to your needs. Additionally, it features a unique dual-roller design that ensures even pressure when laminating. With this machine , you can save time, labor and money while producing superior quality results. It's perfect for both small and large businesses who need to quickly get their windows professionally laminated without any hassle or delay. Invest in the Automatic Vertical Window Laminating Machine with H and see the results for yourself!

1. Servo Motor Feeder, 4 suckers for lifting and 4 suckers for conveying structure. Max Speed 12000 sheets/h

2. The paper feeding table has upper and lower over-limit protection

3.The height of non-stop feeding can reach 1150mm, pre-stacking device, non-stop feeding

4..Intelligent adjustment of front and rear positions of Feeder, just input product data on the control panel

5.BECKER VACUUM PUMP

1.The conveying table adopts customized stainless steel corrugated board

2.The brush wheel and rubber pressing wheel move smoothly

3.Servo motor overlap, improve accuracy of lap, error≤±2mm

1.composed of gluing machine head and infrared oven. After the paper is glued, it is bonded to the film after passing through an infrared oven.

2.Drying unit with 12 pcs IR light, Total heating power 14.4kw.

3.When not using window products, this part can be used as a water powder removing device

1.Glue roller and metering roller are driven by dual independent motors, making adjustment more convenient

2.Drying roller Dia. 1000mm, using double electromagnetic heating system.

3.The heating press roller adopts a segmented heating system, efficient and energy-saving

4.Max pressure of press roller is 12T

5.Gluing system Teflon process treatment, easy to clean and non-sticky

6. One-Touch Start button, input the paper size on screen, feeder/pressing brush wheel/side pull gauge/ disc knife/ paper pat cylinder/ paper baffle board automatic adjustment

1.The paper cutter is equipped with a tension controller and an anti-curl device to ensure that the paper is flat and not curled.

2.The paper cutting part contains grinding wheel, disc knife and chain knife for slitting, meeting customers' requirements for slitting films of different materials

3. The disc knife adpot servo motor control for left and right movement, smooth movement without lagging.

4.The bounce roller is controlled by an independent motor, and the paper can be separated by using the speed difference

5.Hot knife low pressure direct heating and slitting without tail film, detecting paper thickness and slitting, accurate and efficient

1.Adopt pneumatic paper sorting structure to ensure the neatness of the paper and facilitate the next process

2.with a reduction wheel to prevent the paper from being damaged due to too fast hitting the baffle

3.Counting electric eye, the number of running paper is displayed on the display screen at the take-up machine, which can be cleared and accumulated

4.Induction electric eye,sensing the length of the paper, if the length of the paper changes, the belt will accelerate, and the baffle of the take-up machine will overturn and lift the paper

Laminating Questions and Tips

why is my scotch laminator wrinkling

|

Model |

NFM-H1080W |

|

Max. paper size |

1080*1100mm |

|

Min. paper size |

360*290mm |

|

Window patching min size |

390*300mm |

|

Speed |

10-110 m/min |

|

Paper thickness (round knife slitting) |

80-500(≥100gms easy running, suitable for E corrugated) |

|

Paper thickness (hot knife slitting) |

≥115gms |

|

Overlap precision |

≤±1.5mm |

|

Non-stop Feeding height |

1300mm |

|

Collector paper height |

1300 mm |

|

Max heating power |

41.6kw |

|

Working power |

35-45kw |

|

Total power stand by |

75kw |

|

Voltage |

380V 50HZ 3P |

|

Circuit breaker |

160A |

|

working pressure-Mpa |

15 |

|

Weight |

9800kgs |

|

Dimension (layout) |

8400*2630*3000mm |

|

Loading |

40HQ |

|

Large size customize (Width:1280mm,1480mm,1680mm; Length:1280mm,1480mm,1680mm) |

|

Leave Us A Message

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING