Simple Guide For Thermal Lamination Machine

Simple Guide For Thermal Lamination Machine

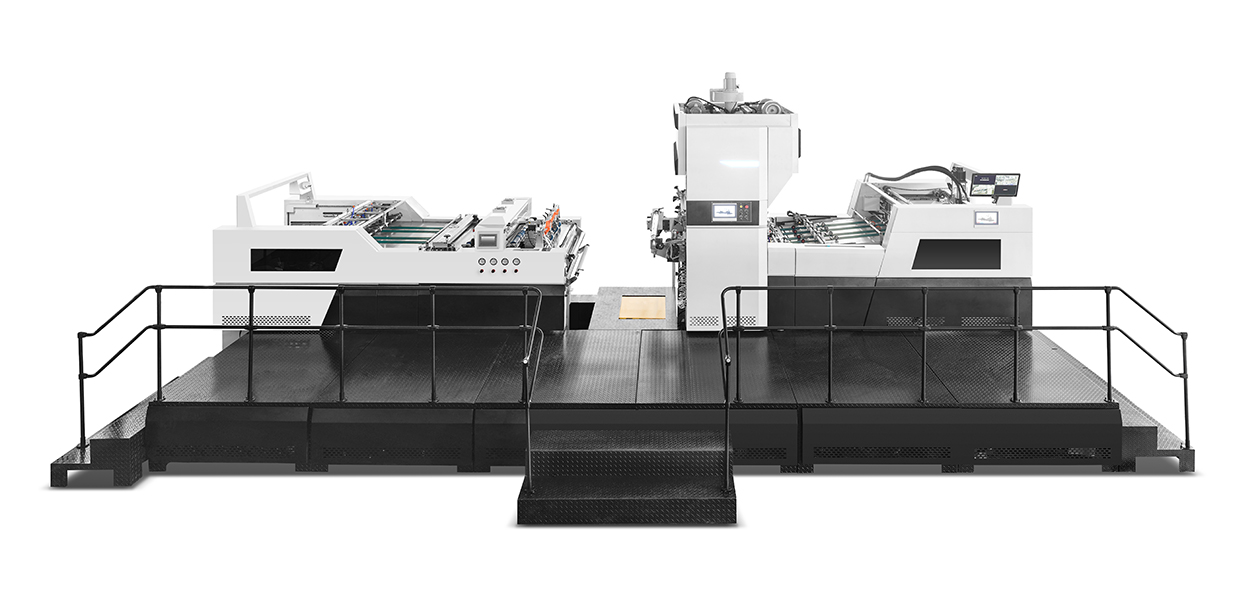

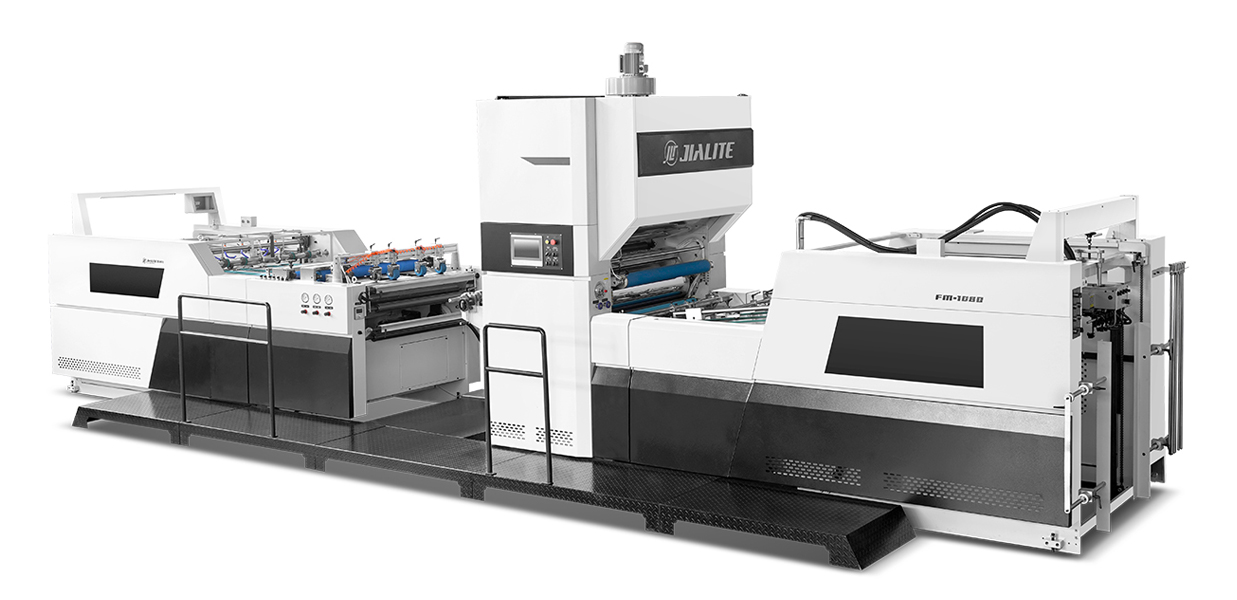

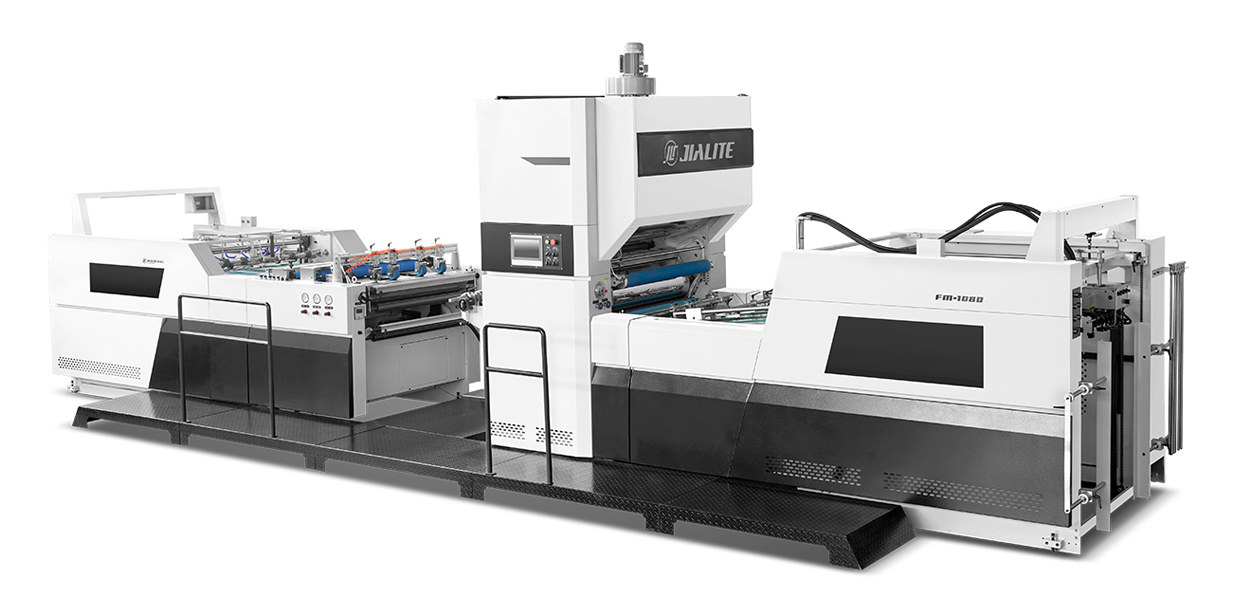

As a thermal lamination machine operator, your responsibilities include setting up the machine, loading documents or other materials into the machine, and running the machine according to specified settings. You must also perform regular maintenance on the machine and keep it clean. In this guide, we will show you how to do all of these things and more.

Thermal lamination is the process of bonding two pieces of material together using heat and pressure. This can be done with a variety of materials, but the most common are plastics. Thermal lamination is often used to create laminated products such as:

-ID cards

-Driver's licenses

-Business cards

-Magnetic stripe cards

-Smartcards

-Etc.

A thermal lamination machine is a versatile piece of equipment that can be used in a variety of settings, from schools and offices to print shops and production facilities. While it is a durable and reliable machine, it still needs to be properly maintained to ensure optimal performance.

Here are some tips on how to keep your thermal lamination machine in top condition:

-Regularly clean the rollers with a lint-free cloth.

-Be sure to use the correct type of laminate film for your project.

-Store the laminate film in a cool, dry place.

-Always use a sharp blade when trimming the laminated sheets.

-Calibrate the machine regularly to ensure proper heat settings.

How to Repair a Faulty Thermal Lamination Machine

Thermal lamination is a process in which heat and pressure are used to adhere a thin film to paper. This method is commonly used to protect documents from wear and tear, as well as to enhance their appearance.

If you have a thermal lamination machine that is not working properly, there are a few things you can do to try and repair it. First, check the power cord and make sure it is plugged into a working outlet. Next, check the laminating film rollers to see if they are dirty or damaged. If they are, clean or replace them. Finally, check the heating element to see if it is functioning properly. If not, replace it.

A faulty thermal lamination machine can be a costly mistake for any business. If you have a laminating machine that is not working properly, it is important to take the time to repair the machine before it causes any further damage. Here are some tips on how to repair a faulty thermal lamination machine:

1. Check the power supply first. If the power supply is not working properly, it could be causing the laminating machine to malfunction.

2. Inspect the rollers and heating elements. If either of these components are not working properly, they will need to be replaced.

3. Clean the laminating machine thoroughly. Over time, dirt and dust can build up on the rollers and heating elements, causing the machine to malfunction.

4. Test the laminating machine after making repairs. Once you have made repairs to the machine, it is important to test it out to make sure that it is working properly again.