Application Of Plastic Film Lamination Machine

Application Of Plastic Film Lamination Machine

Today's food packaging is more than just a container. It's an important part of the product itself. That's why lamination machines are so important in the food industry. By bonding two or more layers of material together, lamination machines create a seal that protects food from contaminants and extends its shelf life.

Lamination machines can bond plastic film to paperboard, aluminum foil, or even other types of plastic film. The most common type of lamination machine used in the food industry is the rotary die cutter. This type of machine uses a cylindrical die that cuts the laminate into the desired shape as it rotates.

Some of the benefits of using a rotary die cutter include:

- Increased production speed

- Reduced waste

- Greater accuracy and precision

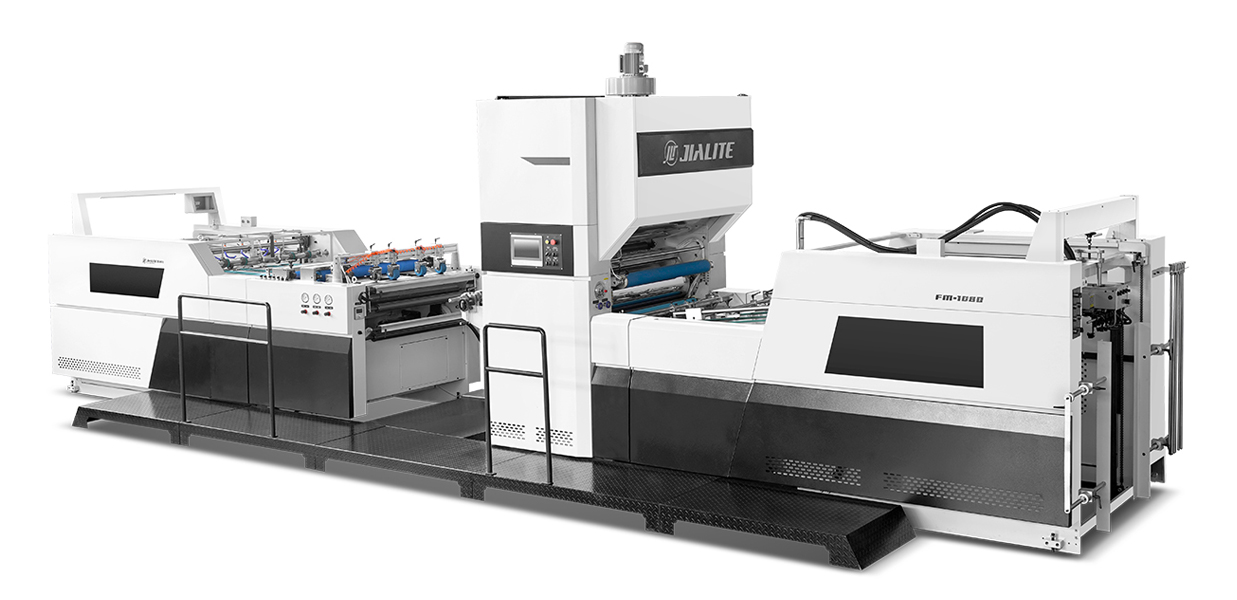

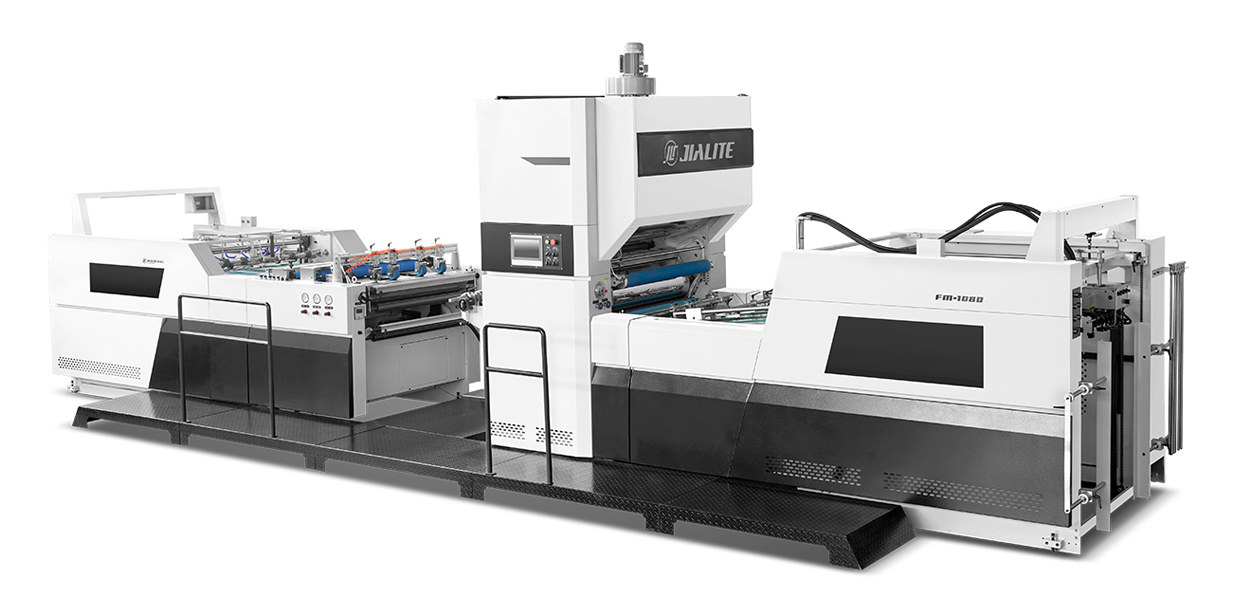

A plastic film lamination machine is a device that can be used to apply a thin layer of plastic film to a substrate. This process is often used in the printing and packaging industry to improve the durability and aesthetics of printed materials. There are many different types of machines available on the market, each with its own set of features and benefits.

When choosing a machine, it is important to consider the type of substrate that will be laminated as well as the thickness and finish of the desired film. Some machines are designed for specific applications, such as hardcover bookbinding or magnetic lamination. Others are more versatile and can be used for a variety of projects.

It is no secret that the lamination process has many advantages. Plastic film lamination can be used in a variety of settings, from the home to the office, and even in industrial settings. The key is to determine which type of lamination machine will best suit your needs. Here are just a few examples of how plastic film lamination can be used:

- To protect important documents: If you have important documents that you need to keep safe, consider laminating them. This will add an extra layer of protection against tearing, water damage, and other potential hazards.

- To enhance the look of posters and other marketing materials: If you want to make a big impression with your marketing materials, consider laminated posters or flyers. Lamination can make colors pop and give your materials a professional look.

- To extend the life of ID cards: If you work in an environment where ID cards are frequently used, such as a hospital or school, it’s important to choose a durable laminate. This will help to extend the life of the card and prevent wear and tear.

Plastic Film Lamination Machine Maintenance Method

1. Check the film before starting the machine.

2. Check the tightness of each screw of the machine.

3. Clean up the dust and dirt on the surface of the machine.

4. Lubricate all lubrication points on time to ensure smooth operation of the parts.

5. Check whether there is any abnormalities in each electrical component and circuit of the machine, and whether the wire connection is firm.

6. After a period of use, check whether all parts are loose or deformed, and deal with them in time if any problems are found

The lamination process is a common way to protect documents and improve their appearance. Many businesses use lamination for items such as menus, ID cards, and product instructions. The process can be done by hand, but it's often more efficient to use a machine.

If you have a business that relies on documents being laminated, then you know how important it is to keep your machine in good working order. Fortunately, there are some easy maintenance tips that you can follow to keep your machine running smoothly.

It is important to keep your plastic film lamination machine clean and well-maintained in order to achieve optimal results. Here are some tips on how to keep your machine running smoothly:

-Wipe down the machine after each use with a damp cloth.

-Clean the rollers regularly with a mild detergent.

-Lubricate the rollers monthly with silicone lubricant.

-Replace the plastic film rolls when they become worn or damaged.