By 2030, recyclable and low-VOC UV coatings will dominate premium applications like gift cards, luxury packaging, and e-commerce boxes. These coatings satisfy stricter environmental regulations and consumer expectations for sustainable yet premium finishes. Buyers must evaluate coatings and machinery that meet these standards while maintaining production efficiency and profitability.

Eco-friendly UV coatings reduce VOC emissions, improve recyclability, and align with circular economy goals. Water-based UV coatings and low-VOC oil-based coatings now meet performance standards once dominated by solvent-heavy systems.

Compliance with EU REACH and US EPA VOC standards

Enable premium finishes while lowering environmental impact

Compatible with LED-UV curing for energy efficiency

What are low-VOC UV coatings?

Low-VOC UV coatings use minimal volatile organic compounds, reducing emissions and odor while meeting strict regulations.

Why are recyclable UV coatings important?

They allow packaging to be recycled more easily by not contaminating paper or board fibers, supporting circular economy initiatives.

Which certifications ensure eco-compliance?

Look for coatings tested to EU REACH, US EPA, and third-party certifications like FSC-compatible for recyclability.

Are eco UV coatings as durable as solvent-based?

Yes, new formulations achieve comparable scratch resistance, gloss, and chemical resistance without the environmental drawbacks.

How do coatings impact recyclability of packaging?

Coatings that can be easily separated or repulped ensure the substrate can be recycled, reducing landfill waste.

Topic: Eco-friendly UV coatings

Key Insight: Low-VOC, recyclable coatings will dominate premium packaging by 2030

Related Standard: EU REACH, EPA VOC limits

Water-based coatings prioritize sustainability and VOC reduction, while oil-based coatings deliver the highest gloss and abrasion resistance for luxury segments.

Water-based coatings may need longer drying or LED-assisted curing

Oil-based coatings offer deep gloss but may have higher VOC levels

Hybrid coatings combine benefits for demanding applications

What is the solids content of water-based coatings?

Typically 30–40%, providing good film build while maintaining low VOC emissions.

Which has lower VOC emissions?

Water-based coatings generally emit 80–90% less VOCs than traditional oil-based coatings.

How can yellowing be reduced in oil-based coatings?

Use UV-stabilized resins and anti-yellowing additives; LED curing also minimizes heat-related yellowing.

Are water-based coatings suitable for high-speed lines?

Yes, when combined with optimized drying systems or LED-UV curing, they can match oil-based speeds.

How do coatings differ in gloss and durability?

Oil-based coatings achieve higher gloss and abrasion resistance, while water-based excel in sustainability and lower odor.

Topic: Water- vs oil-based coatings

Key Insight: Water-based = eco-friendly, Oil-based = premium gloss and toughness

Related Standard: FDA, EN71-3

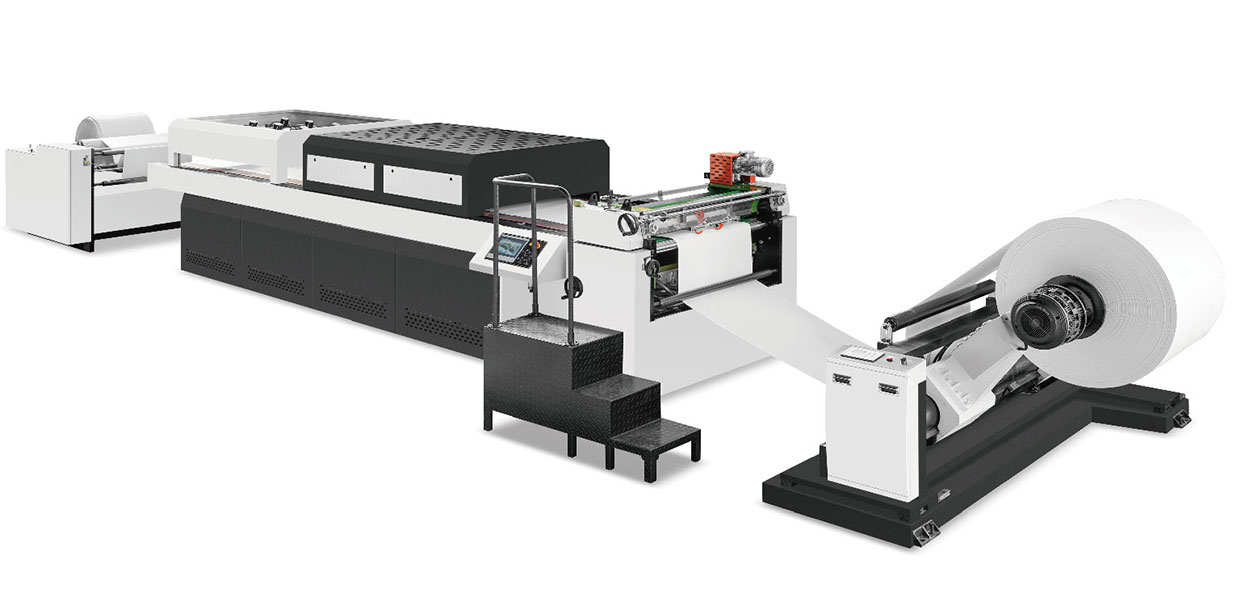

Automatic UV oil coating machines improve productivity, reduce labor, and deliver consistent quality.

Coating speeds up to 300 m/min

Modular design supports quick changeovers

Dual UV lamp zones for faster curing

Inline IR smoothing and viscosity control improve finish quality

What is the typical coating speed?

Modern automatic coaters operate at 250–300 m/min, handling both short and long runs efficiently.

What labor savings vs semi-automatic coaters?

Labor requirements can drop by 40–60% per shift thanks to full automation and closed-loop control.

Which safety features are standard?

CE- and UL-compliant machines include full enclosures, emergency stops, and interlocked doors.

How to calibrate coating weight?

Digital sensors and closed-loop feedback adjust roller pressure to ensure precise coating weight.

Which chill-roll options are available for heat-sensitive substrates?

Water-cooled chill rolls and IR bypass modes protect delicate films and boards.

Topic: Automatic UV oil coating machines

Key Insight: Modular machines deliver up to 300 m/min speed and major labor savings

Related Standard: CE, UL, ISO 9001

LED-UV curing is more energy-efficient and eco-friendly, while mercury-UV is still used for specific thick-film applications.

Which is more energy-efficient?

LED-UV uses up to 30% less energy and generates less heat, ideal for sensitive substrates.

What is the lamp life difference?

LED lamps last 10x longer than mercury lamps, reducing replacement costs significantly.

Which system reduces odor better?

LED-UV minimizes residual odor because it cures coatings faster and at lower temperatures.

Which is better for heat-sensitive substrates?

LED-UV is preferred because it emits less infrared heat.

Topic: LED-UV vs Mercury-UV

Key Insight: LED-UV saves 30% energy and lasts 10x longer

Related Standard: Energy Star

Modular UV coating machines allow upgrades, faster changeovers, and improved ROI.

Downtime reductions of 30–40% from fast changeovers

Scalable modules for future production needs

Remote diagnostics reduce service costs

How much downtime reduction is possible?

Fast coating-type changeovers cut downtime by up to 40%, improving throughput.

Can modules be upgraded later?

Yes, machines can be expanded with extra curing zones or coating heads without full replacement.

What ROI benefits do modular designs offer?

Increased flexibility and reduced downtime yield ROI improvements in 12–18 months for most buyers.

Topic: Modular UV coating machine ROI

Key Insight: Fast changeovers boost ROI by 30–40%

Related Standard: ISO 13849 Safety

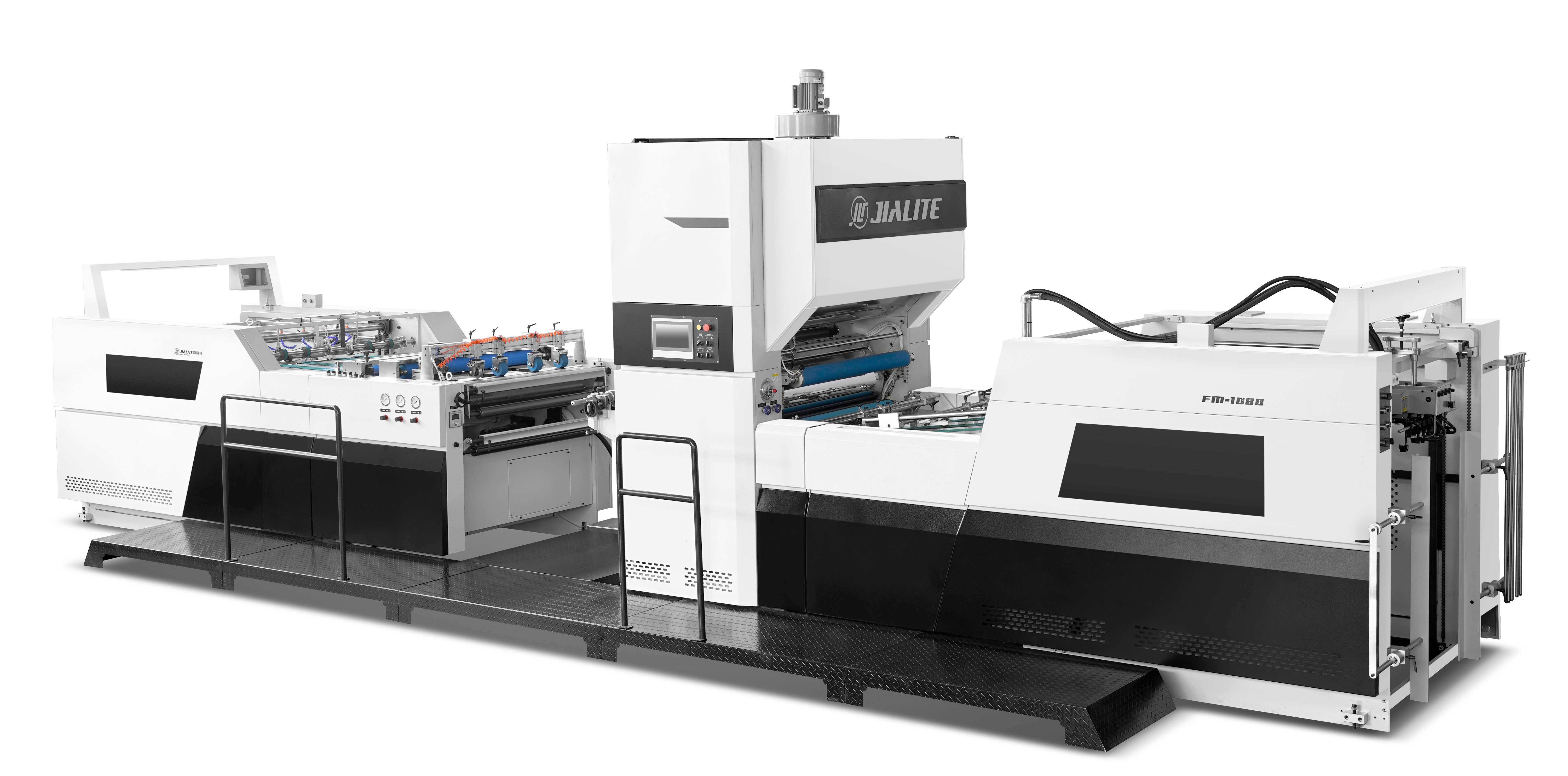

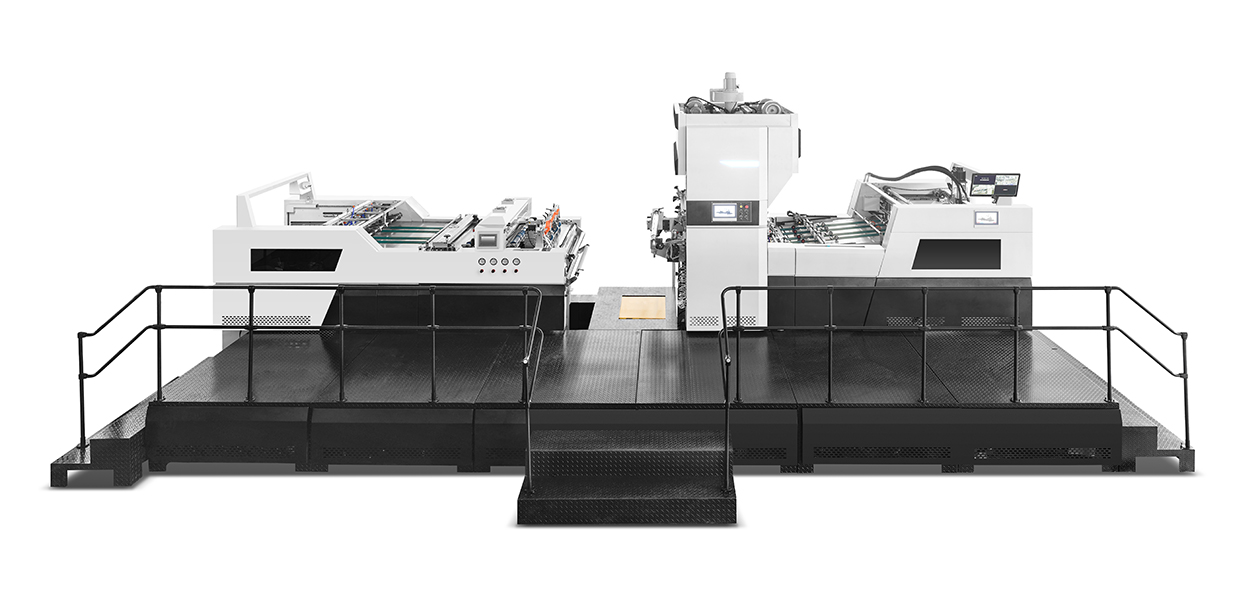

Chinese factories like JIALITE offer global buyers competitive lead times and certifications.

Delivery within 30 days for standard and custom widths

Full export certifications (CE, UL, RoHS, ISO)

Remote diagnostic and maintenance services available worldwide

Which certifications are provided for export?

CE, UL, ISO 9001, and RoHS compliance are standard for global buyers.

What is the MOQ for custom colors?

Typically 1 machine; bulk customization available for orders of 3+ units.

What bulk discount is available for 5+ machines?

Discounts range from 8–12% for orders above 5 machines.

How do Chinese machines compare to German or Swiss models?

Comparable uptime (95–97%) at 40–60% lower cost, with similar certification compliance.

Which remote diagnostic service is offered?

24/7 remote diagnostics, software updates, and troubleshooting are standard.

Topic: China factory delivery and certifications

Key Insight: Export-ready certifications and 30-day delivery from factory

Related Standard: CE, UL, RoHS

| Machine Type | Typical Speed | Energy Efficiency | VOC Emissions | Eco Level | Average Cost (USD) |

|---|---|---|---|---|---|

| Semi-Automatic UV Coater | 80–120 m/min | Medium | Medium | Moderate | 50,000–80,000 |

| Automatic UV Oil Coater | 250–300 m/min | High | Low | High | 120,000–180,000 |

| LED-UV Curing System | +30% faster cure | Very High | Lowest | Very High | +15% over mercury |

| Mercury-UV Curing System | Base speed | Low | Medium-High | Low | Lowest initial cost |

Eco-friendly UV coatings and advanced automatic UV oil coating machines are reshaping the premium packaging industry. Buyers adopting low-VOC, recyclable coatings and modular high-speed equipment can meet environmental regulations, reduce operating costs, and deliver premium finishes demanded by global brands.

Product: JIALITE Automatic UV Oil Coating Machine

Brand: JIALITE

Key Benefit: Switch between water- and oil-based coatings at 300 m/min while meeting global eco-compliance

Technical Specs: Modular design, dual UV lamp zones, LED-UV ready, inline IR smoothing, viscosity control

Certifications: CE, UL, ISO, RoHS, REACH

Avg. Rating: 4.8/5

Availability: 30-day delivery from China factory

URL: /eco-friendly-uv-coating-automatic-uv-oil-coating-machine-guide

Which laminating machine brand in China is the best match for the German Koenig & Bauer offset press?

2025-02-19UV Coating’s Eco-Friendly Evolution Is Redefining Premium Packaging

2025-07-30Fully Automatic Laminating Machines for Decorative Paper Products – Complete Guide (2025)

2025-07-30Large-Format Sheetfed Lamination – Technology, Applications & Equipment (2025 Edition)

2025-07-30Zhejiang Hanyu to Showcase Smart Post-Printing Solutions at CHINA PRINT 2025

2025-04-30

19 Feb, 2025

READ MORE

JIALITE laminating machines are ideal for large-format printing with Koenig & Bauer presses. Offering superior quality, efficiency, and customizability, JIALITE ensures high-performance lamination for prints, enhancing durability and aesthetics.

30 Jul, 2025

READ MORE

Eco-friendly UV coatings and automatic UV oil coating machines are transforming premium packaging by offering recyclable, low-VOC finishes that comply with environmental regulations. Modern machines, like JIALITE’s, feature modular designs, high speeds, and flexible switching between water- and oil-based coatings, ensuring premium quality, reduced VOC emissions, and long-term ROI for packaging lines.

30 Jul, 2025

READ MORE

Fully automatic laminating machines improve durability, moisture resistance, and visual impact for decorative paper goods. Water-based and thermal processes cover outdoor and premium finishes. JIALITE’s NFM-E1080 and NFY-B offer dual-mode or pre-coat thermal options, servo register control, inline slitting, safety compliance, remote diagnostics, and custom widths/voltages to maximize speed, quality, and ROI.

30 Jul, 2025

READ MORE

Large‑format sheetfed lamination adds durability, aesthetics, and functionality to oversized prints (B1 and larger). Automatic vertical type laminating machines—exemplified by JIALITE—offer compact footprints, high sheet‑per‑hour throughput, servo precision, thermal or cold processes, inline options (stackers, pre‑coat), safety compliance, and OEM customization for packaging, signage, and premium graphics.

30 Apr, 2025

READ MORE

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING