Mobile laminators are a more compact, lightweight and portable version of traditional laminating machines. By utilizing battery-powered motors, these devices provide convenient operation and ease-of-use that often eliminates the need for an external power supply or additional accessories. Unlike the traditional machines, these mobile versions incorporate multiple rollers for higher-speed performance, so users can quickly produce laminated documents in nearly any environment. Additional differences between the two include temperature control settings to suit different types of pouches, along with adjustable pressure settings which help achieve better clarity and results. Thanks to their aerodynamic design and robust construction, mobile laminators can also often withstand heavy usage without losing its effectiveness over time.

Mobile lamination machines offer a great deal of benefits in terms of efficiency, convenience and cost savings. For businesses on-the-go, mobile lamination machines allow them to laminate documents and items quickly and easily in any location. Documents that must be kept clean can also be laminated at any time. In addition, many mobile lamination machines are designed to use smaller size rolls than traditional stationary laminators, allowing for maximum portability and space savings. Moreover, the cost savings realized from using a mobile machine for lamination can add up over time, especially when completed tasks need not take up precious office real estate.

Mobile lamination machines provide a modern and convenient way for laminating documents. Utilizing high-grade heated lamination technology, these machines offer the perfect solution for various lamination projects such as ID cards, menus, book covers and other important documents. As their name implies, mobile lamination machines are small enough to fit into homes or offices easily, with no need for permanent installation. They operate at low noise levels while also featuring adjustable speed control to allow users to tailor their experience. Furthermore, they are equipped with multiple pockets to accommodate documents of different sizes and thickness so that users can laminate items quickly without compromising quality. With the right features and ease of use, mobile lamination machines make it easy to achieve professional results in minimum time.

Keeping a mobile lamination machine in working order requires regular maintenance. It is important for both the longevity and function of the machine to make sure it is regularly serviced and maintained. To do this, mobile lamination machines should be inspected on a consistent basis for loose parts and frayed wires. Additionally, it is helpful to clean off machine components every so often to remove dust. Lastly, any necessary adjustments or replacements should be made in accordance with the specific makeup of your machine. With regular maintenance, a mobile lamination machine will serve you faithfully for years to come.

Lamination machines have become an essential tool for many businesses and individuals. They protect and preserve documents, photos, cards, and other materials from wear and tear, spills, and fading. With so many options on the market today, it can be confusing to determine which type of lamination machine is best suited for your needs.

When it comes to choosing a lamination machine, there are several different types available on the market. Each type of machine has its own benefits and drawbacks depending on your specific needs.

The first type of lamination machine is the pouch laminator. This type of machine uses pre-cut sheets or pouches that are fed into the machine and sealed around the document being laminated. Pouch laminators are typically smaller in size and more portable than other types of laminators, making them ideal for home or office use. However, they may not be suitable for larger documents or high-volume lamination jobs.

Another popular type of lamination machine is a roll laminator.

Laminating machines are an essential tool for anyone who wants to preserve their documents, photos, and artwork for longer periods. These machines protect these materials from damage caused by water, dust, and wear and tear that come with frequent handling. There are different types of laminating machines available in the market today. Each type has its unique features that make it ideal for specific tasks.

The most common type of laminating machine is the pouch laminator. As the name suggests, this machine uses a pouch to encase your document or photo in plastic before running it through heated rollers that seal the layers together. Pouch laminators are best suited for small-scale lamination projects such as ID cards, luggage tags, and menu cards. They are also affordable and easy to use.

Another type of laminating machine is the roll-to-roll or thermal laminator.

Laminator paper is an essential component of the lamination process. It is a thin, transparent sheet that is coated on one or both sides with a heat-activated adhesive. Laminating paper can be used to protect and preserve important documents such as photographs, certificates, and ID cards.

There are several different types of laminator paper available in the market today. The first type is glossy laminating paper which provides a high-gloss finish to the document. This type of laminating paper is ideal for creating visually attractive posters, flyers or presentations that require vibrant colors and sharp images.

The second type of laminator paper is matte laminating paper which has a duller finish compared to its glossy counterpart. This type of laminating paper is perfect for documents that require low glare levels such as menus, maps or instructional materials.

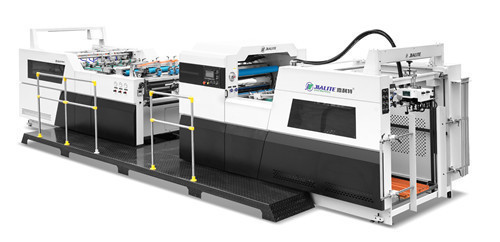

GREAT since from 1995. Continuous introduction the European concept of equipment manufacturing, based on more than 20 years experience, we focus on the development and innovation of laminating machine and UV coating machine, GREAT provide efficiency products and reasonable post press solution to every user.

Company structure is scientific and reasonable with humanized management mechanism. The ERP management system and 5S standard are used to ensure the strict system of development,procurement, processing, production and assembly, factory inspection, packaging and logistics.Mature customer service system, the domestic First-tier and second-tier cities have direct selling and service branch, technical engineers team at any time provide after-sale consultation and arrangement installation and troubleshooting service for foreign customers.

Daily maintenance of coating machine

2022-02-24Care and maintenance of coating machine

2022-02-21Application field of automatic coating machine

2022-01-21How to choose Automatic coating machine manufacturers

2022-01-1824 Feb, 2022

READ MORE

The transmission and moving parts of the newly installed coating machine must be inspected, tightened, refueled and maintained within a week of use; after that, regular inspection and maintenance must be carried out every month.

21 Feb, 2022

READ MORE

Ensure that the coating equipment is installed horizontally. It should be grounded, and an independent leakage switch should be installed for safe use.

21 Jan, 2022

READ MORE

Liquid ink manufacturing for testing ink shade/strength and coatings.

18 Jan, 2022

READ MORE

Due to the lack of in-depth understanding, most friends do not know which part of Automatic coating machine manufacturers to choose to obtain satisfactory results. In fact, as long as we have the patience to explore more things, we will soon know that manufacturers that have been established for many years, while focusing on the industry, have cooperated with different customers, and they will definitely have strong strength.

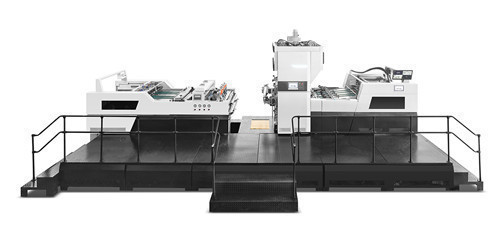

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING