Paper lamination machines provide an easy, cost-effective solution for professional-looking documents. There are several different types of paper lamination machines available to meet the needs of any project, including ultra-thin pouch machines, thermal pouch machines, and combination roll laminators. Ultra-thin pouch laminators are perfect for smaller projects and quick turnarounds such as ID cards, business cards, and other small items that need a glossy finish.

Thermal pouch laminators are perfect for certificates and larger projects since they use thicker pouches that are more durable than their ultra-thin counterparts. Combination roll laminators offer the versatility of both pouch and roll machines combined with just one unit; making them ideal for high volume operations where both large production runs and occasional short runs are common. Having the right type of machine ensures a high quality final product in no time at all!

When it comes to purchasing a paper lamination machine for your business, finding the right price can make all the difference. Everyone wants to get the highest quality machine that suits their specific needs, but at a reasonable cost. Doing thorough research will give you an idea of what prices to expect; there is certainly great variability due to features and capabilities of different models. Shopping around and making comparisons can help you find the best deal while also ensuring you get top-notch materials and parts with plenty of special features. Ultimately, finding the right paper lamination machine doesn't have to break the bank if you know how to compare prices and look for sales.

A lamination machine consists of several parts that work together to encase documents in plastic. The components of this machine include a hot plate, heated rollers, a heat film, and a conveyor belt. These parts all work in conjunction to uniformly apply the heat film over the material being laminated. The quality of these components largely affects how well the process works and how good the result looks - it's important to choose machines with reliable parts, such as rustproof hot plates and roller bearings that offer precise, durable control. This will ensure that documents are covered evenly and with only minimal warping or peeling over time.

Proper maintenance of lamination machine parts is essential for reliable and quality performance, longevity and safety. Depending on the type of lamination machine, maintenance may include daily cleaning, monthly lubrication and periodic inspections. Ensuring that the machine is properly installed and aligned before use should also be a priority. Each part should be inspected, cleaned, lubricated or replaced if necessary. It's important to check for signs of wear such as broken wires, fraying, cracks or dirt to ensure that everything is running smoothly and reliably over time. Following these steps at regular intervals can help prolong the life of your lamination machine parts and keep them operating efficiently and safely for years to come.

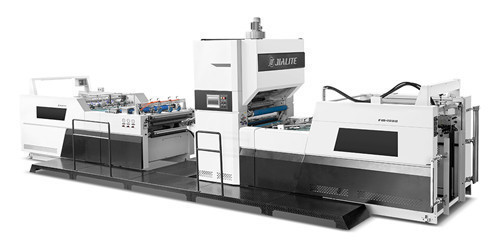

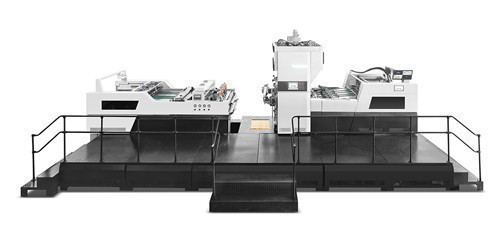

GREAT since from 1995. Continuous introduction the European concept of equipment manufacturing, based on more than 20 years experience, we focus on the development and innovation of laminating machine and UV coating machine, GREAT provide efficiency products and reasonable post press solution to every user.

Company structure is scientific and reasonable with humanized management mechanism. The ERP management system and 5S standard are used to ensure the strict system of development,procurement, processing, production and assembly, factory inspection, packaging and logistics.Mature customer service system, the domestic First-tier and second-tier cities have direct selling and service branch, technical engineers team at any time provide after-sale consultation and arrangement installation and troubleshooting service for foreign customers.

Daily maintenance of coating machine

2022-02-24Care and maintenance of coating machine

2022-02-21Application field of automatic coating machine

2022-01-21How to choose Automatic coating machine manufacturers

2022-01-1824 Feb, 2022

READ MORE

The transmission and moving parts of the newly installed coating machine must be inspected, tightened, refueled and maintained within a week of use; after that, regular inspection and maintenance must be carried out every month.

21 Feb, 2022

READ MORE

Ensure that the coating equipment is installed horizontally. It should be grounded, and an independent leakage switch should be installed for safe use.

21 Jan, 2022

READ MORE

Liquid ink manufacturing for testing ink shade/strength and coatings.

18 Jan, 2022

READ MORE

Due to the lack of in-depth understanding, most friends do not know which part of Automatic coating machine manufacturers to choose to obtain satisfactory results. In fact, as long as we have the patience to explore more things, we will soon know that manufacturers that have been established for many years, while focusing on the industry, have cooperated with different customers, and they will definitely have strong strength.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING