Automatic thermal laminating machines are a valuable tool for enhancing documents and increasing their durability.

Designed to apply a layer of protective coating to paper, these machines use heat and pressure to bond a plastic film onto the surface.

To use an automatic thermal laminating machine, simply place the document inside a laminating pouch or feed it through the machine if using a roll laminating machine.

The machine will then heat up and activate the adhesive on the laminating film, sealing it onto the document.

The finished laminated document is now protected from moisture, tears, and other forms of damage, making it ideal for long-term use.

Not only does laminating enhance the appearance and longevity of documents, but it also provides them with a professional and polished look.

By understanding the basics of automatic thermal laminating machines and their benefits, you can select the right machine for your needs and create high-quality laminated documents.

Automatic thermal laminating machines work by using heat and pressure to bond a plastic film onto the surface of a document, providing a layer of protection. To use the machine, the document is placed inside a laminating pouch or fed through the machine if using a roll laminating machine. The machine heats up and activates the adhesive on the laminating film, sealing it onto the document. This process enhances the appearance and durability of the document, making it resistant to moisture, tear, and other damage. Laminating also gives the document a professional and polished look. These machines are versatile and can be used for various types of documents, such as photos, ID cards, signage, and more. By understanding the basics of automatic thermal laminating machines, you can effectively utilize them to create high-quality laminated documents.

Using an Automatic Thermal Laminating Machine offers several benefits. Firstly, it enhances the appearance of documents, giving them a professional and polished look. Secondly, it provides durability by protecting documents from moisture, tears, and other damage. Thirdly, laminated documents are easier to clean and maintain, making them ideal for long-term use. Additionally, laminating increases the lifespan of documents, minimizing the need for reprints. Moreover, it improves the readability of documents by reducing glare and increasing contrast. Furthermore, laminating offers a convenient and efficient way to preserve important documents, such as ID cards, signage, or certificates. Lastly, by utilizing an automatic machine, the laminating process becomes faster and more consistent, increasing productivity. Overall, the benefits of using automatic thermal laminating machines make them an essential tool for businesses, schools, and individuals seeking to protect and enhance their documents.

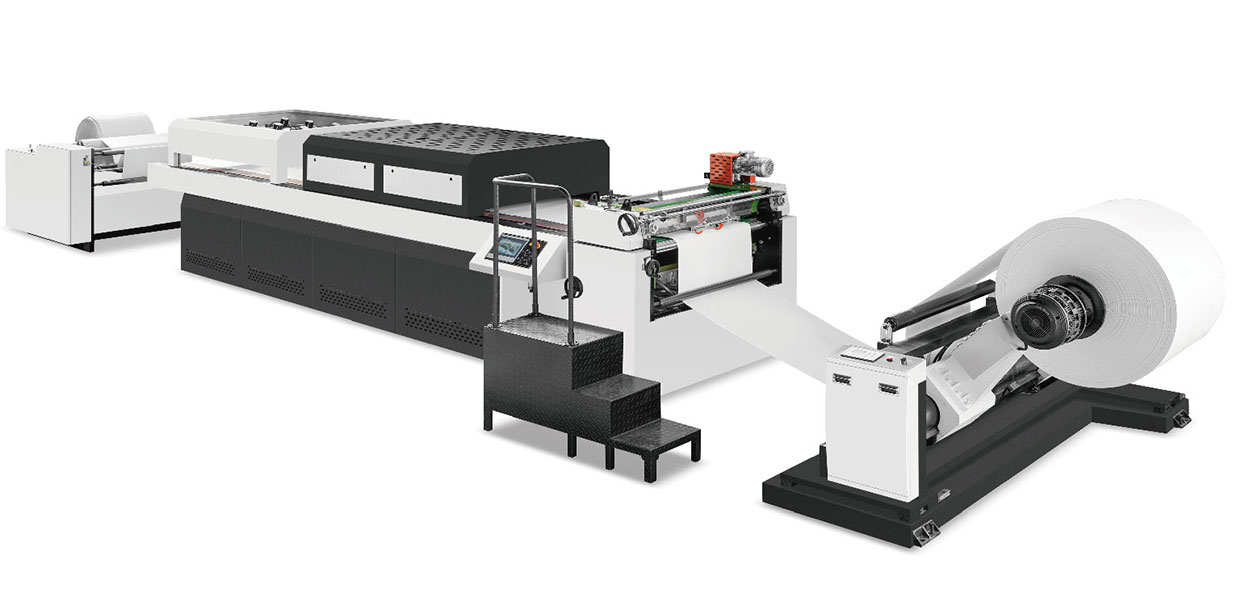

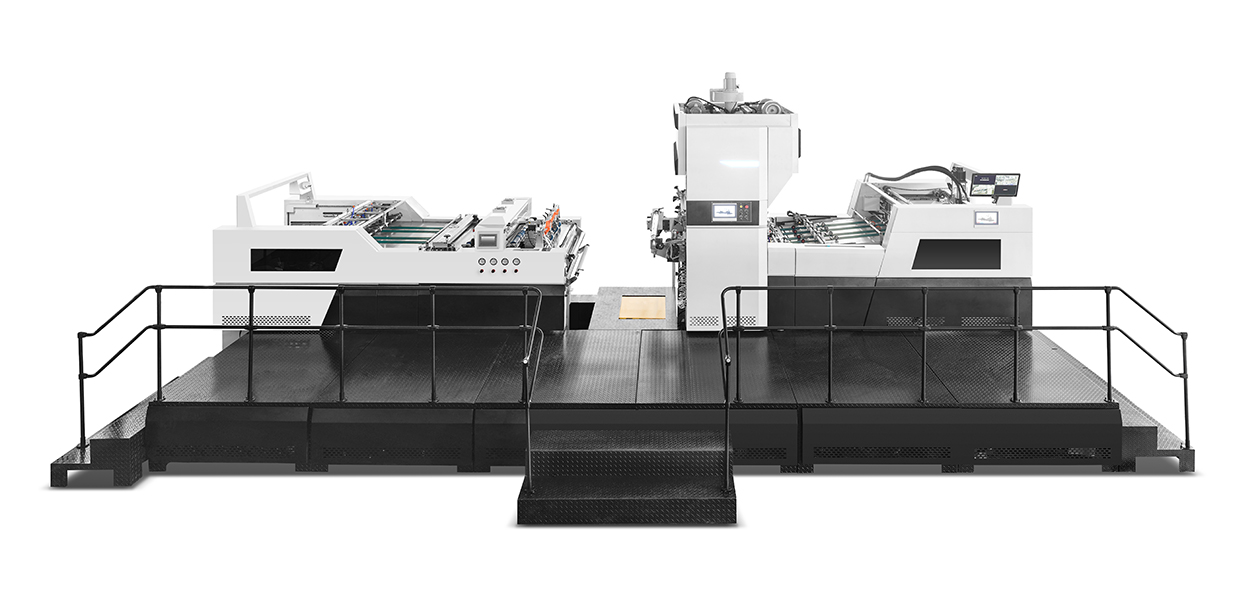

There are two main types of Automatic Thermal Laminating Machines: roll laminating machines and pouch laminating machines. Roll laminating machines use rolls of laminating film, which are fed through the machine to laminate documents of various sizes. Pouch laminating machines, on the other hand, use pre-sealed pouches that are inserted into the machine along with the document to be laminated. Pouch laminating machines are typically more convenient for smaller documents, while roll laminating machines are better suited for larger documents or continuous laminating tasks. Some automatic thermal laminating machines offer multifunctionality, allowing users to not only laminate but also cut and trim documents in one machine. These different types of machines cater to different needs and preferences, providing options for a range of laminating applications.

Roll laminating machines and pouch laminating machines are two main types of automatic thermal laminating machines, each with its own advantages and preferred usage. Roll laminating machines use rolls of laminating film, allowing for continuous lamination of larger documents and materials. On the other hand, pouch laminating machines use pre-sealed pouches, making them more convenient for smaller documents and ensuring a sealed and protected finish. The choice between the two depends on the size and nature of the documents being laminated, as well as the desired level of convenience and efficiency.

Multifunctional Automatic Thermal Laminating Machines offer added versatility and convenience, allowing users to not only laminate documents but also cut them into desired shapes and sizes. These machines often feature adjustable settings for temperature and speed to accommodate various laminating materials and thicknesses. Some models also offer additional functionalities such as hole punching, corner rounding, and even laminating both sides of a document simultaneously. This makes multifunctional laminating machines ideal for businesses and individuals who require diverse laminating needs, such as creating ID badges, posters, menus, or marketing materials. Investing in a multifunctional automatic thermal laminating machine can save time and money by eliminating the need for separate machines or manual cutting, while still providing professional and polished laminated products.

When purchasing an automatic thermal laminating machine, there are several considerations to keep in mind. Firstly, it's essential to assess the speed and capacity features of the machine to ensure it meets your requirements. Additionally, considering the size and compatibility with laminating materials is crucial to ensure the machine can handle the desired document sizes and thicknesses. Another factor to consider is the availability and cost of replacement parts and laminating film, as these will be necessary for ongoing maintenance. It is also recommended to read reviews and seek recommendations to ensure the machine is reliable and easy to use. Finally, checking for warranty and customer support options can provide peace of mind and assistance if any issues arise. By carefully considering these factors, you can make an informed decision and choose the right automatic thermal laminating machine for your needs.

When purchasing an automatic thermal laminating machine, it is crucial to consider the speed and capacity features. Look for machines that can handle the volume and speed of laminating that you require. Consider the laminating capacity per hour and the number of sheets that can be laminated at once. Machines with higher speed and capacity will allow you to complete your laminating tasks more efficiently. Additionally, check for features like adjustable speed, temperature control, and multiple rollers, as these can improve the overall performance and versatility of the machine. By prioritizing speed and capacity features, you can ensure that your automatic thermal laminating machine meets your specific laminating needs.

Size and compatibility with laminating materials is another vital consideration when purchasing an automatic thermal laminating machine. Ensure that the machine is capable of accommodating the size of documents or items you need to laminate. Check the maximum width and length specifications provided by the manufacturer. Additionally, pay attention to the types of laminating materials that can be used with the machine. Some machines may be limited to using specific types or thicknesses of laminating film. It is essential to choose a machine that is compatible with the materials you intend to use. Taking these factors into account will ensure that you select a machine that can effectively handle the size and type of laminating projects you have in mind.

Operating an automatic thermal laminating machine is a straightforward process that involves a few simple steps:

Power on the machine and allow it to warm up to the desired laminating temperature.

Place the document or item you want to laminate into the laminating film or pouch, ensuring that it is centered and aligned correctly.

Insert the laminating film or pouch into the machine, guiding it through the rollers or feeding trays.

The machine will automatically feed the document and laminating film through the machine, applying heat and pressure to fuse them together.

Once the laminating process is complete, the laminated document will be ejected from the machine.

Trim any excess laminating film or pouch to achieve the desired finished size.

Remember to follow the manufacturer's instructions for any specific settings or adjustments required for your particular automatic thermal laminating machine. Regularly clean and maintain the machine to ensure optimal performance and longevity.

To use an Automatic Thermal Laminating Machine, follow these simple steps:

Power on the machine and allow it to warm up to the desired laminating temperature.

Place the document or item you want to laminate into the laminating film or pouch, ensuring it is centered and aligned correctly.

Insert the laminating film or pouch into the machine, guiding it through the rollers or feeding trays.

The machine will automatically feed the document and laminating film through, applying heat and pressure to fuse them together.

Once the laminating process is complete, the laminated document will be ejected from the machine.

Finally, trim any excess laminating film or pouch to achieve the desired finished size.

Remember to follow the manufacturer's instructions for specific settings or adjustments and regularly clean and maintain the machine for optimal performance and longevity.

To ensure the longevity of your Automatic Thermal Laminating Machine, here are some maintenance tips:

Regularly clean the machine using a lint-free cloth and mild cleaning solution to remove any adhesive residue or debris.

Check the rollers and feeding trays for any signs of wear or damage, and replace them if necessary.

Lubricate the moving parts of the machine according to the manufacturer's instructions to prevent friction and keep it running smoothly.

Keep the machine in a clean and dust-free environment to avoid particles interfering with its operation.

Store the laminating films or pouches in a cool, dry place to prevent them from becoming brittle or warped.

If the machine has adjustable temperature settings, avoid running it at the highest temperature all the time to prevent overheating and potential damage.

Follow the recommended maximum capacity for laminating materials to prevent overloading the machine.

Remember, proper maintenance will not only extend the lifespan of your machine but also ensure consistent and high-quality laminating results.

If the machine is jammed, turn it off and unplug it before attempting to remove the jammed material.

Carefully pull the jammed material out, making sure not to tear or damage it.

Clean the rollers and feeding trays to remove any debris that may have caused the jam.

Restart the machine and test it with a small piece of laminating material to ensure the jamming issue is resolved.

Check the temperature settings of the machine and adjust them if necessary.

Ensure that the laminating material is not too thick or too thin for the machine's capabilities.

Clean the rollers and feeding trays to remove any adhesive residue that may be affecting the quality of lamination.

If the issue persists, contact the manufacturer for further assistance or consider having the machine serviced by a professional technician.

Remember to always follow the manufacturer's instructions and guidelines when troubleshooting issues with your automatic thermal laminating machine.

When using an automatic thermal laminating machine, it is not uncommon to encounter jamming problems. Here are some steps to help you identify and fix these issues:

First, turn off and unplug the machine to ensure your safety.

Carefully remove the jammed material, taking care not to tear or damage it.

Take the time to clean the rollers and feeding trays to remove any debris that may have caused the jam.

Once everything is clean and clear, restart the machine and test it with a small piece of laminating material to ensure the problem is resolved.

By following these steps, you should be able to troubleshoot and fix any jamming problems with your automatic thermal laminating machine, allowing you to continue using it for your laminating needs.

To deal with overheating issues in your automatic thermal laminating machine, check the temperature settings and ensure they are at the appropriate level for the laminating materials being used. Clean the machine's cooling fans and make sure they are functioning properly. If the laminating quality is poor, consider adjusting the pressure settings or using different laminating materials. Check the rollers for any debris or damage that may be affecting the lamination process. If necessary, replace worn-out rollers or seek professional assistance for repairs. Regularly maintain and clean your laminating machine to prevent overheating and ensure optimal lamination results.

As you conclude your journey through the essential guide to understanding automatic thermal laminating machines, remember these key points. Automatic thermal laminating machines offer efficient and high-quality lamination options for various materials. When choosing a machine, consider the type that suits your needs, such as roll laminating machines or pouch laminating machines. Look for speed, capacity, and compatibility features before making a purchase. Operating the machine requires following step-by-step instructions and regular maintenance to prolong its lifespan. When facing issues like jamming, identify the cause and troubleshoot accordingly. Finally, for overheating or poor lamination quality, adjust temperature and pressure settings, clean and maintain the machine regularly, and replace worn-out rollers if necessary. By following these guidelines, you'll ensure optimal performance and quality results from your automatic thermal laminating machine.

Automatic thermal laminating machines offer efficient and high-quality lamination options for various materials. When choosing a machine, consider the type that suits your needs, such as roll laminating machines or pouch laminating machines. Look for speed, capacity, and compatibility features before making a purchase. Operating the machine requires following step-by-step instructions and regular maintenance to prolong its lifespan. When facing issues like jamming, identify the cause and troubleshoot accordingly. For overheating or poor lamination quality, adjust temperature and pressure settings, clean and maintain the machine regularly, and replace worn-out rollers if necessary. By following these guidelines, you'll ensure optimal performance and quality results from your automatic thermal laminating machine.

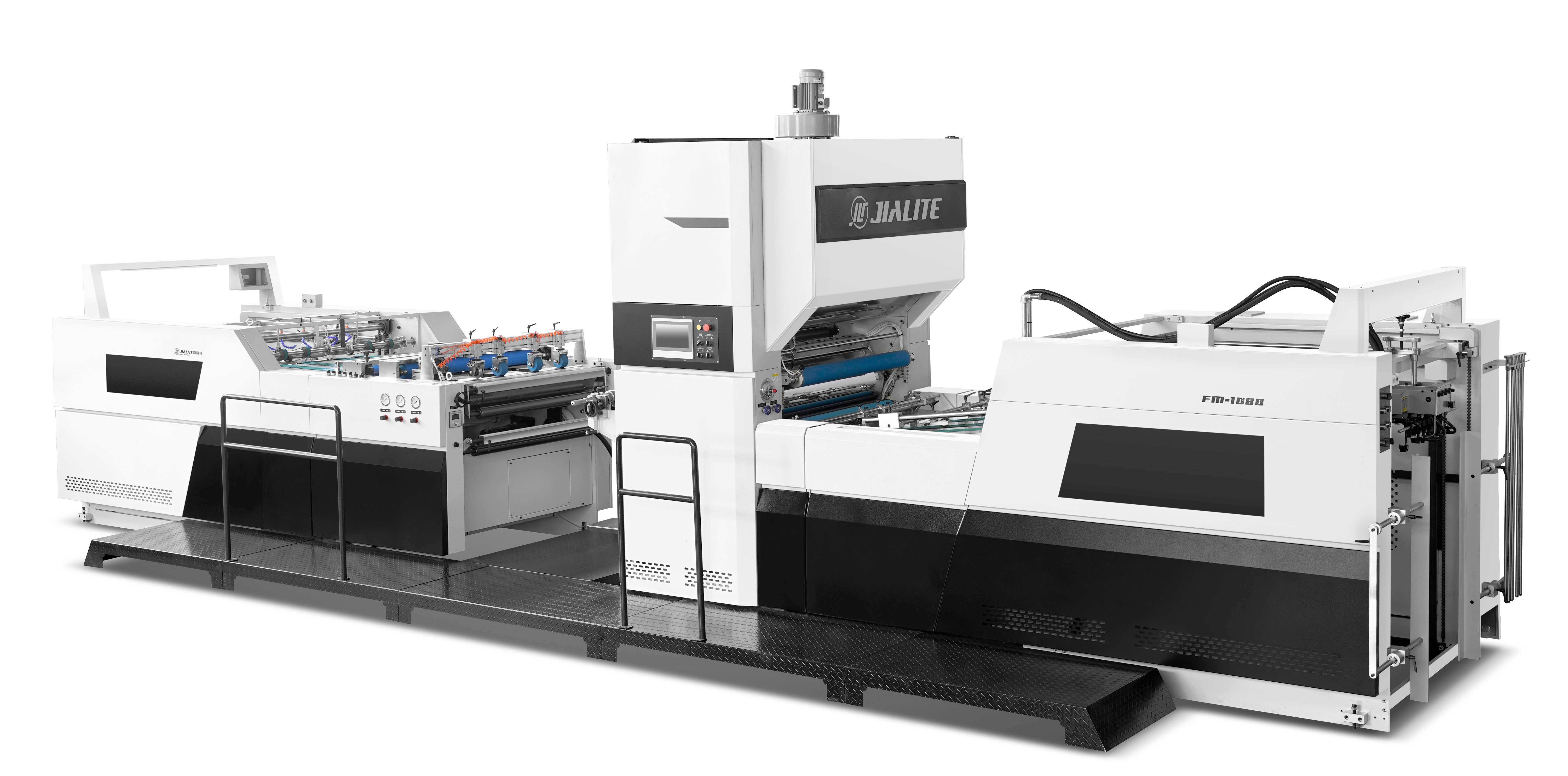

Why Choose JIALITE for Your Coating Machines?

2024-03-23Exploring Window Film Laminating Technology: Adding Convenience and Appeal to Your Products!

2024-04-11The Essential Guide to Understanding Automatic Thermal Laminating Machines

2024-07-19Environmental Impact of UV Coating Technology

2024-07-12EXPOGRÁFICA 2024 --12th-15th November Meet you in Mexico

2024-11-05Enhance Efficiency in Printing, Packaging, and Paper Processing with Jialite’s Varnishing & Laminating Machine Support

2024-11-01Optimize Production with the SG-AR1200 Automatic Roll-to-Roll UV Oil Varnish Coating Machine

2024-11-01Custom Laminating Solutions by Jialite for Tag and Cosmetic Box Manufacturers

2024-11-01

23 Mar, 2024

READ MORE

JIALITE is a trusted global leader in high-precision coating and laminating machines, offering cutting-edge solutions for printing, packaging, and paper processing industries. With decades of expertise, customized designs, and reliable support, JIALITE is your ideal partner for boosting production efficiency and quality.

11 Apr, 2024

READ MORE

Window film laminating technology not only provides an attractive display for products but also enhances consumer shopping experience and convenience. As an advanced packaging technique, it will continue to play a significant role in various industries, offering new possibilities and creativity in product packaging.

19 Jul, 2024

READ MORE

Discover the essentials of automatic thermal laminators, including their basics, types, operation methods, and maintenance tips. Choose the right laminator to enhance document appearance and durability. This guide covers laminator usage steps, solutions to common issues, and purchasing advice, helping you maximize the versatility and efficiency of your laminator.

12 Jul, 2024

READ MORE

Discover the environmental benefits of UV coating machines and strategies for energy efficiency and emission reduction. Explore how Automatic UV Oil Coating Machines contribute to sustainability in manufacturing processes.

05 Nov, 2024

READ MORE

Differentiation creates value, and service moves customers; Garrett paper finishing technology makes printed matter a work of art, which is widely spread...

01 Nov, 2024

READ MORE

For the printing, packaging, and paper processing sectors, Jialite offers comprehensive installation, technical support, and operator training for varnishing and laminating machines. Our on-site services help companies in flexible packaging and corrugated carton production achieve seamless integration and maximum efficiency.

01 Nov, 2024

READ MORE

The SG-AR1200 by Jialite is an automatic roll-to-roll UV oil varnish coating machine designed for high-quality, durable coating applications. Ideal for packaging, printing, and corrugated carton manufacturing industries, this machine offers versatile oil compatibility and adjustable speeds, ensuring superior results.

01 Nov, 2024

READ MORE

Jialite offers customized laminating solutions for tag manufacturers and cosmetic box creators, enhancing production efficiency and quality. Our solutions include multi-roll laminating, double side laminating, chain knife slitting, and vibrant digital ink laminating options—ideal for the printing and packaging industries.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING