The NFM-E800 high speed automatic vertical laminating machine is designed for high-precision, multi-duty lamination. It is ideal for applying plastic films to the surface of paper printed materials, and it supports the following lamination methods:

| Specification | NFM-E800 |

|---|---|

| Max Paper Size | 780*800mm |

| Min Paper Size | 260*230mm |

| Speed | 10-100m/min |

| Paper Thickness | 80-500gsm (Above 100gsm, E-type corrugated paper) |

| Overlap Precision | ≤±2mm |

| Non-Stop Feeding Height | 1050mm |

| Collector Paper Height (Incl. Pallet) | 1050mm |

| Power Supply | 380V-50Hz-3P |

| Working Pressure | 0.9Mpa |

| Cable Thickness | 25mm² |

| Machine Weight | 5000kgs |

| Machine Dimension (Layout) | 605023502570mm |

| Loading Type | 20GP |

What types of lamination does the machine support?

Can the machine handle different film materials?

Is the machine equipped with a non-stop feeding system?

What is the maximum speed of the machine?

What is the maximum paper size the machine can handle?

How does the cutting system work?

What is the power supply requirement?

Does the machine come with a tension control system?

What is the working pressure of the machine?

Is glue application uniform?

JIALITE’s laminating machines are renowned for their high efficiency and precision. Key advantages include:

Learn more: High Speed Automatic Vertical Laminating Machine Certificate

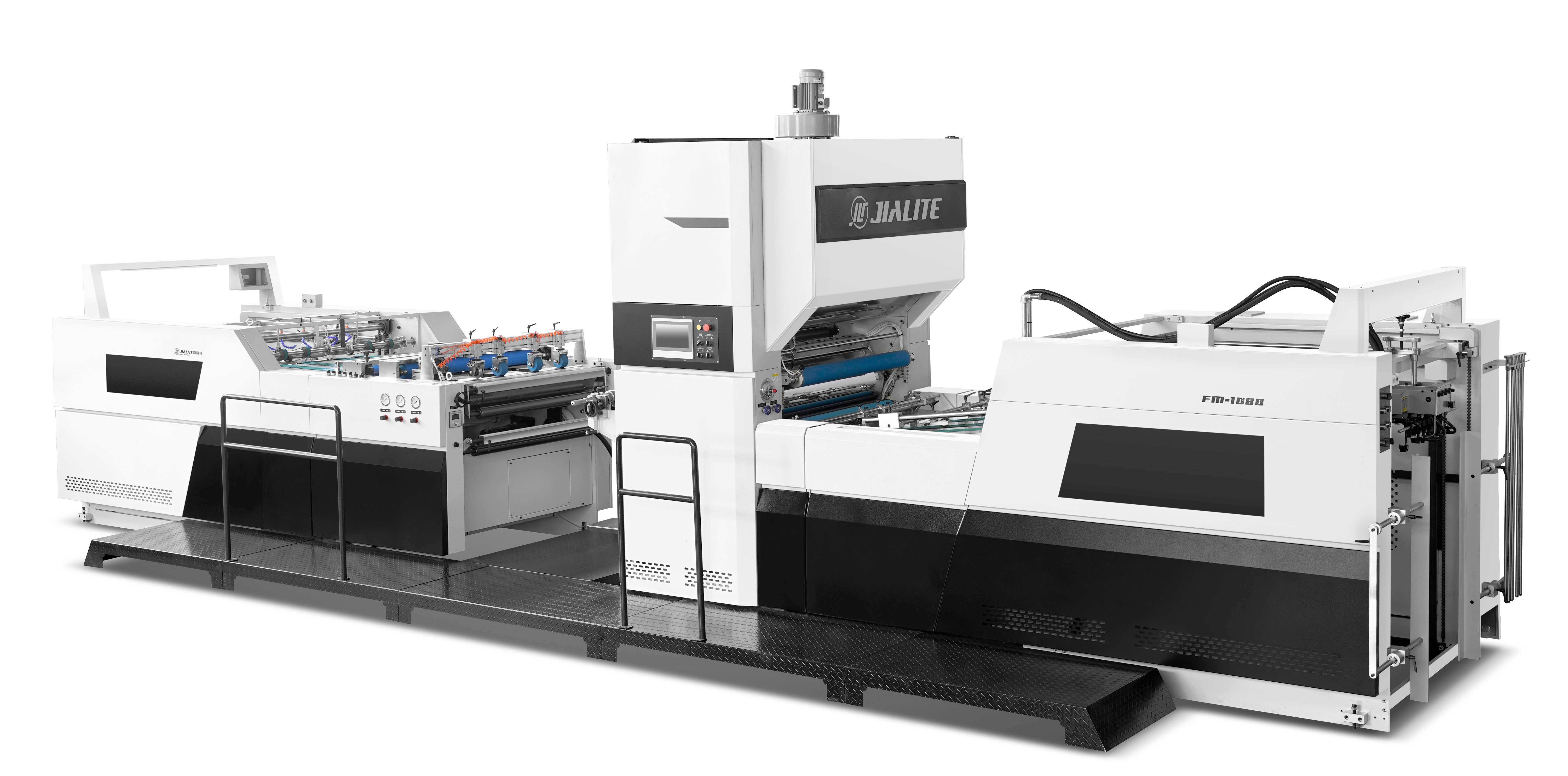

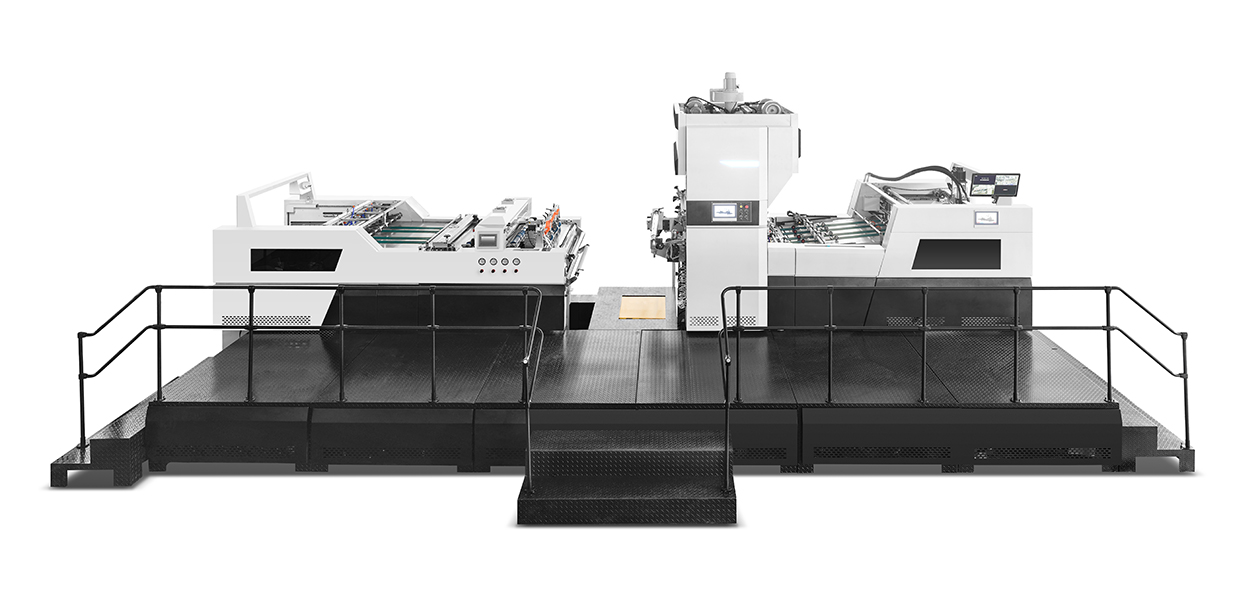

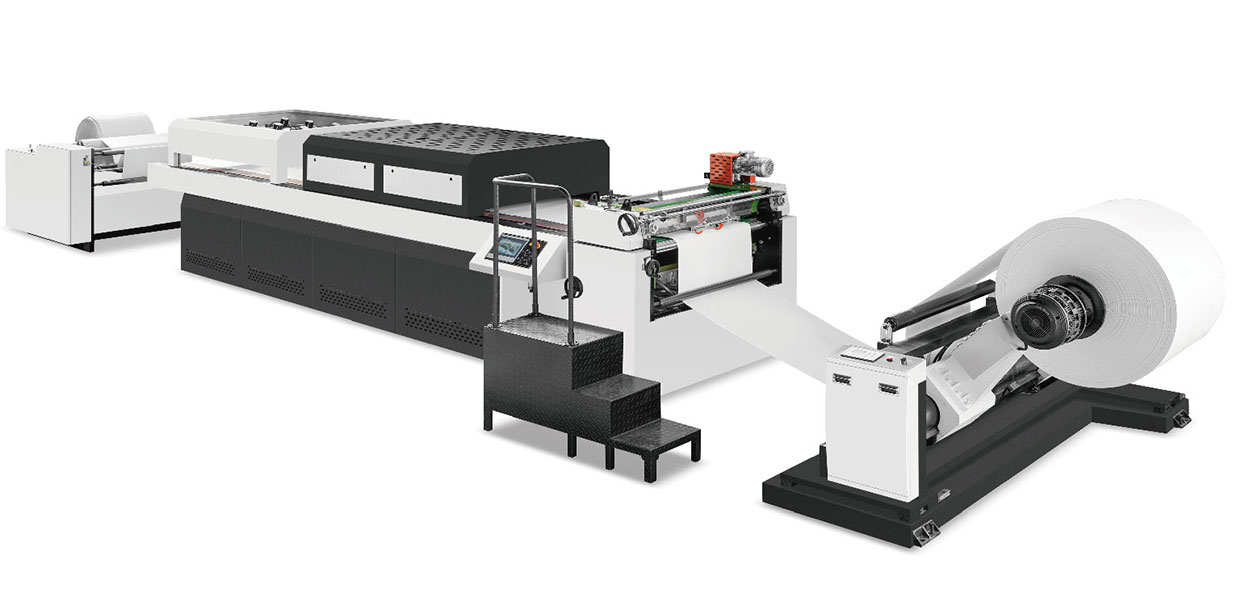

Automatic Roll to Roll Laminating Machine | High-Precision Laminating Solutions NFM-ER800/1080/1380

2024-09-18AUTOMATIC ROLL TO ROLL LAMINATING MACHINE | High-Precision Laminating Solutions

2024-09-11Enhance Efficiency in Printing, Packaging, and Paper Processing with Jialite’s Varnishing & Laminating Machine Support

2024-11-01Optimize Production with the SG-AR1200 Automatic Roll-to-Roll UV Oil Varnish Coating Machine

2024-11-01

18 Sep, 2024

READ MORE

The NFM-ER800/1080/1380 Automatic Roll to Roll Laminating Machine offers advanced lamination for a wide range of applications, including packaging, books, magazines, and gift boxes. With support for water-based and thermal lamination, it is perfect for laminating OPP, PET, PVC, and metallic films. The machine provides dust-proof, water-proof, and oil-resistant lamination for enhanced product quality. Customization options are available, and it is suitable for laminating businesses of all sizes.

11 Sep, 2024

READ MORE

The NFM-ER800/1080/1380 Automatic Roll to Roll Laminating Machine offers state-of-the-art laminating technology, supporting thermal and water-based lamination for a wide range of film types including OPP, PET, PVC, and metallic films. It is perfect for applications in packaging, books, cartons, calendars, and more, with customizable sizes to suit individual needs.

01 Nov, 2024

READ MORE

For the printing, packaging, and paper processing sectors, Jialite offers comprehensive installation, technical support, and operator training for varnishing and laminating machines. Our on-site services help companies in flexible packaging and corrugated carton production achieve seamless integration and maximum efficiency.

01 Nov, 2024

READ MORE

The SG-AR1200 by Jialite is an automatic roll-to-roll UV oil varnish coating machine designed for high-quality, durable coating applications. Ideal for packaging, printing, and corrugated carton manufacturing industries, this machine offers versatile oil compatibility and adjustable speeds, ensuring superior results.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING