Meeting the Demands of Modern Printing

The printing industry is experiencing a shift towards personalization and increased complexity. To address these challenges, Jialite has developed modular post-press equipment that combines standardization with flexibility. Our fully automatic laminating machines and UV oil coating machines are designed to optimize production processes and adapt to diverse requirements.

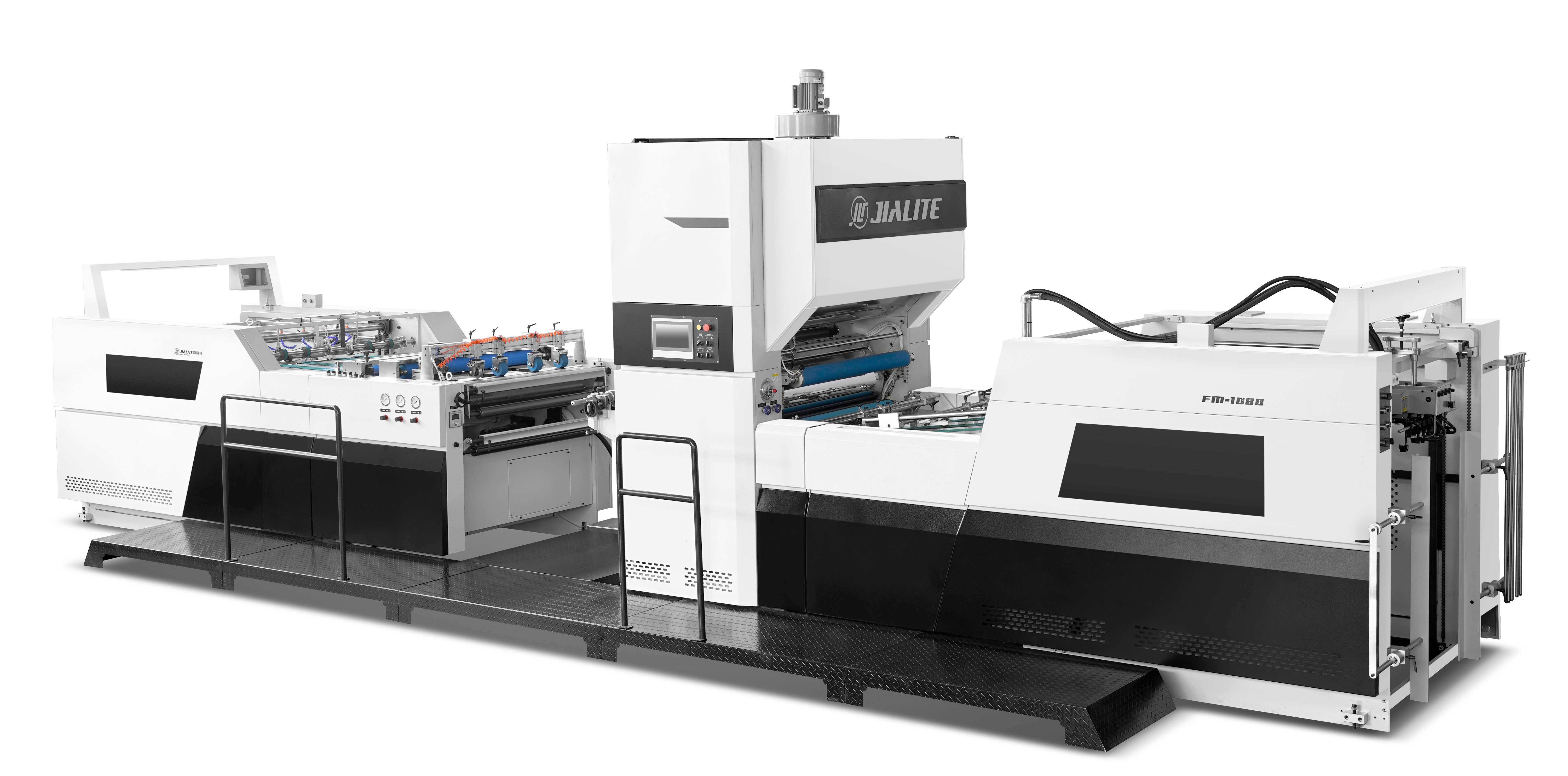

Fully Automatic Laminating Machines: Efficiency and Precision

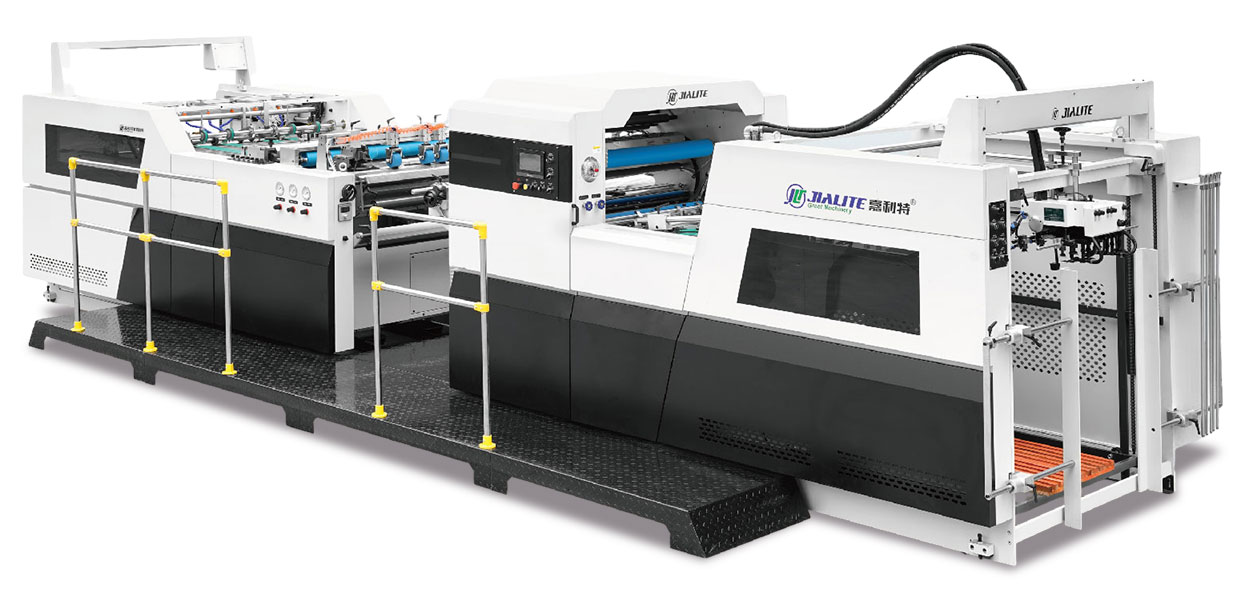

Jialite's fully automatic laminating machines offer high-speed performance and precise lamination, ensuring consistent quality across various applications. These machines are equipped with advanced features such as automatic feeding, laminating, trimming, and stacking, which streamline the workflow and reduce manual intervention. The modular design allows for easy integration of additional functionalities, catering to specific production needs.

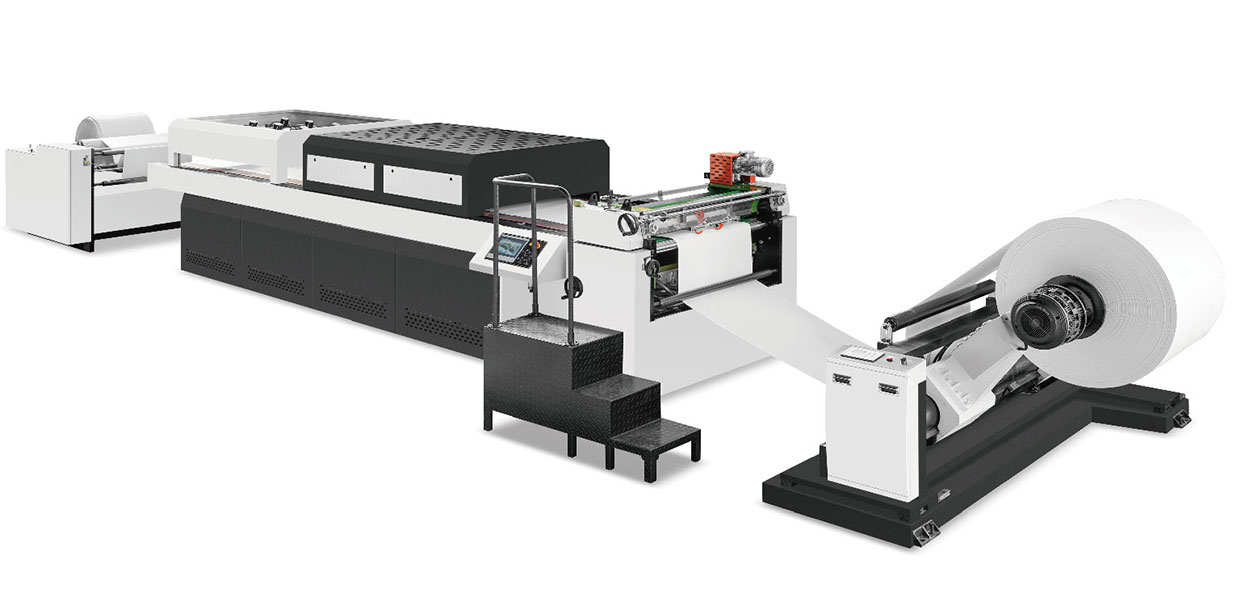

UV Oil Coating Machines: Enhancing Durability and Aesthetics

Our UV oil coating machines apply protective coatings to printed materials, enhancing their durability and visual appeal. The machines utilize advanced drying and curing systems, including infrared and ultraviolet lamps, to ensure rapid and uniform results. With adjustable settings, they can handle a range of substrates and coating thicknesses, providing versatility for various packaging solutions.

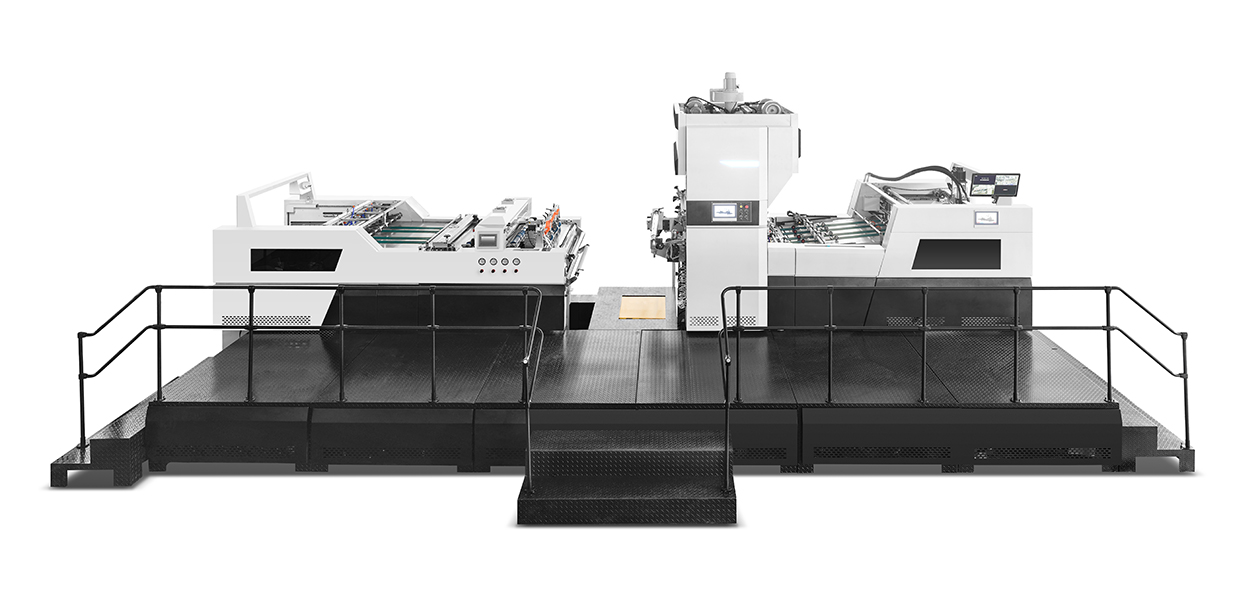

Modular Design: Customizable Post-Press Solutions

Jialite's modular approach enables customers to customize their post-press equipment configurations. By incorporating option devices, businesses can tailor the machinery to their specific requirements, enhancing adaptability and competitiveness in a dynamic market. This modularity supports scalability and future upgrades, ensuring long-term value.

Benefits of Jialite's Modular Post-Press Equipment

-

Flexibility: Customize configurations to meet unique production needs.

-

Efficiency: Automated processes reduce manual labor and increase throughput.

-

Quality: Advanced technologies ensure consistent and high-quality finishes.

-

Scalability: Modular design allows for easy upgrades and integration of new functionalities.

-

Sustainability: Energy-efficient systems contribute to eco-friendly operations.

Call to Action

Explore how Jialite's modular post-press solutions can enhance your printing and packaging operations. Contact us today to learn more about our fully automatic laminating machines and UV oil coating machines.

Product FAQ China UV Oil Coating Machines Manufacturers, Suppliers, Factory

Q1: What materials can Jialite's laminating machines handle?

A1: Our laminating machines are designed to process a variety of materials, including paper, cardboard, and specialty films, accommodating different thicknesses and finishes.

Q2: How does the UV oil coating machine enhance product durability?

A2: The UV oil coating machine applies a protective layer that increases resistance to scratches, moisture, and UV exposure, extending the lifespan of printed materials.

Q3: Can the equipment be customized for specific production needs?

A3: Yes, our modular design allows for the integration of option devices, enabling customization to meet specific operational requirements.

Q4: What is the maintenance requirement for these machines?

A4: Our machines are designed for easy maintenance, with accessible components and user-friendly interfaces to minimize downtime.

Q5: Are Jialite's machines energy-efficient?

A5: Yes, our equipment incorporates energy-saving technologies, contributing to sustainable manufacturing practices.

Q6: How does the modular design benefit scalability?

A6: The modular design allows businesses to start with a base configuration and add functionalities as needed, supporting growth and adaptation to changing demands.

Q7: What is the production speed of the laminating machines?

A7: Our fully automatic laminating machines offer high-speed operation, significantly increasing production efficiency.

Q8: Can the UV oil coating machine handle different coating types?

A8: Yes, the machine is compatible with various coatings, including UV varnish and water-based coatings, providing versatility for different applications.

Q9: Is training provided for operating the equipment?

A9: We offer comprehensive training and support to ensure optimal operation and maintenance of our equipment.

Q10: How does Jialite ensure product quality?

A10: We implement rigorous quality control measures and utilize advanced technologies to ensure our equipment meets high-performance standards.

Modular Laminating Machines: Enhancing Flexibility in Post-Press Processing

The adoption of modular laminating machines allows printing businesses to adapt quickly to market changes and customer demands. By enabling easy integration of new functionalities, these machines support a wide range of applications, from commercial printing to specialized packaging solutions. The flexibility offered by modular design is essential for businesses aiming to stay competitive in a dynamic industry.

UV Coating Equipment: Advancements in Surface Finishing

UV coating equipment has revolutionized surface finishing by providing durable and visually appealing coatings. The technology ensures rapid curing and high-quality finishes, enhancing the aesthetic and protective qualities of printed materials. This advancement is particularly beneficial for packaging applications where product presentation and durability are critical.

Customizable Post-Press Solutions: Meeting Diverse Industry Needs

Customizable post-press solutions are vital for addressing the diverse requirements of the printing and packaging industries. By offering equipment that can be tailored to specific production needs, businesses can optimize their operations, improve efficiency, and deliver high-quality products that meet customer expectations.

Flexible Printing Equipment: Adapting to Market Trends

The demand for flexible printing equipment is growing as businesses seek to adapt to evolving market trends. Equipment that offers modularity and customization enables companies to respond swiftly to changes in customer preferences and production demands, ensuring sustained competitiveness and growth