In the dynamic world of printing and packaging, the Automatic Vertical Laminating Machine stands as a cornerstone for enhancing the quality and durability of printed materials. This article delves into the intricacies of laminating methods, shedding light on the diverse techniques employed by this cutting-edge machinery.

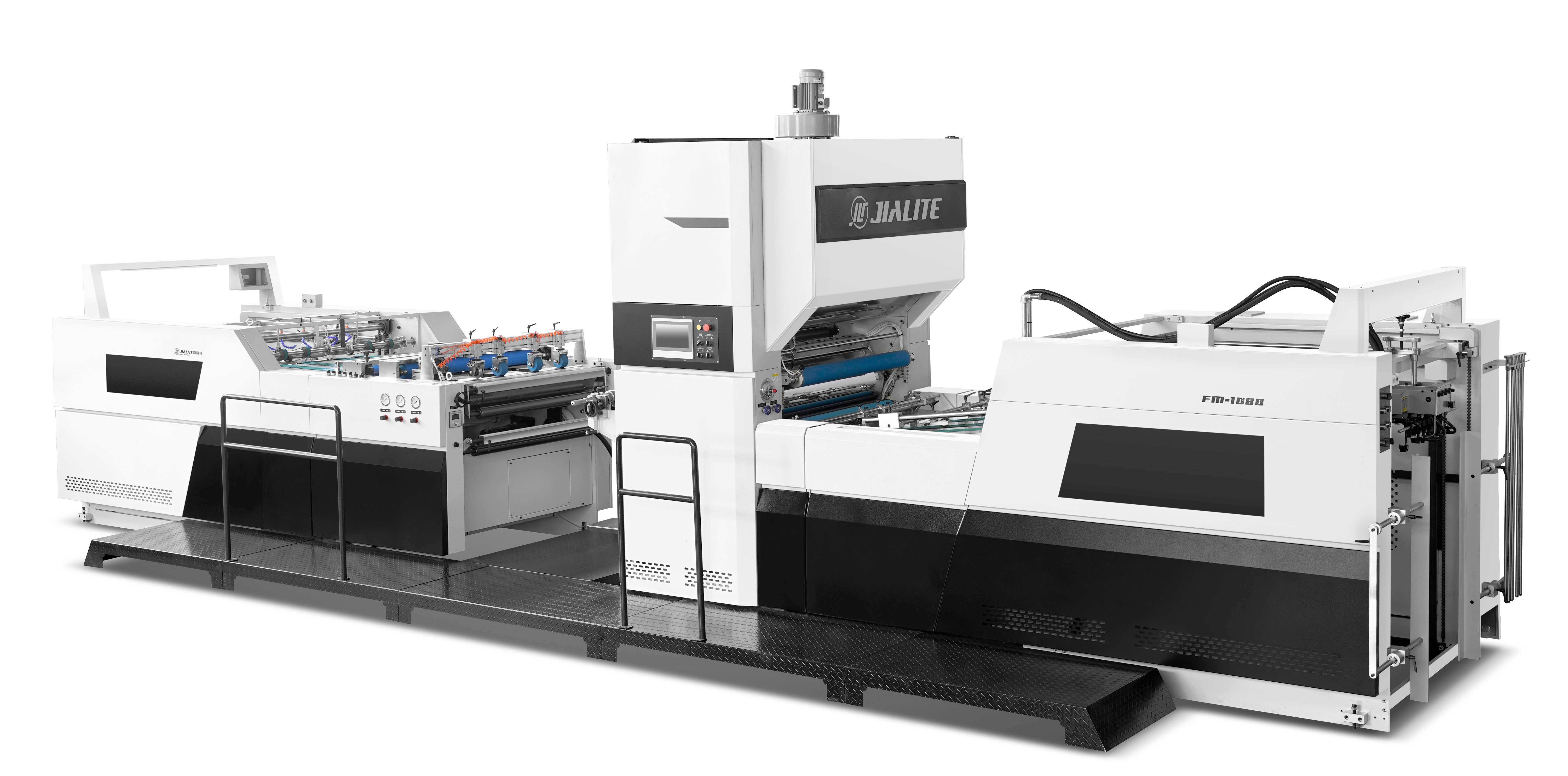

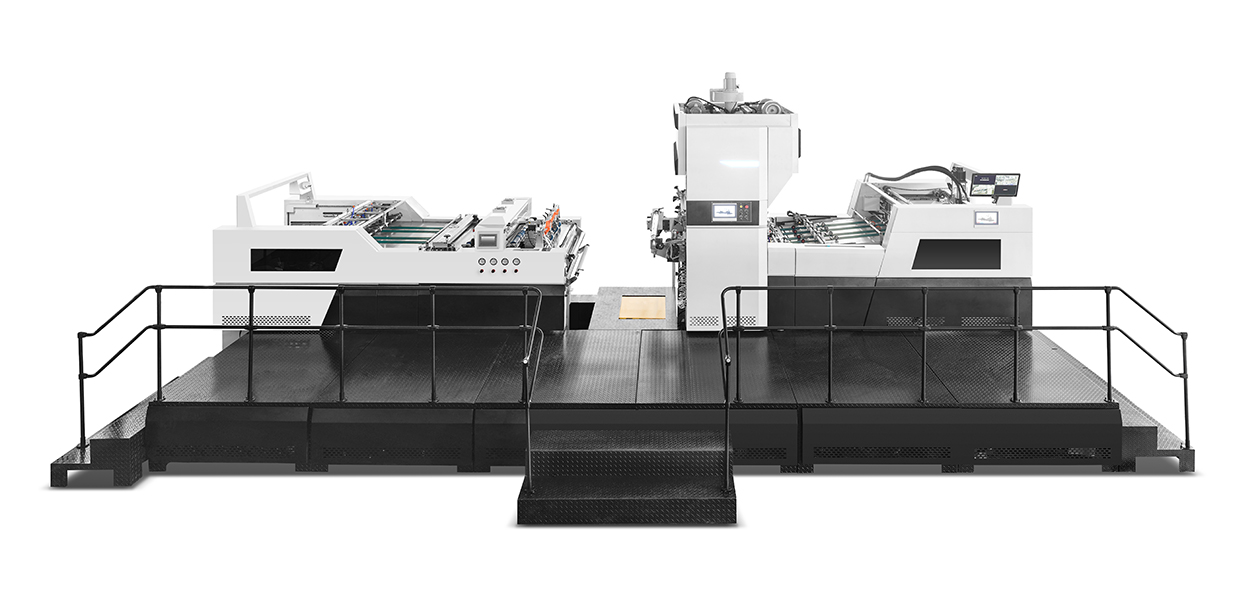

Before delving into the laminating methods, let's grasp the essence of the Automatic Vertical Laminating Machine. This sophisticated equipment is designed for seamlessly combining layers of materials to enhance their strength, appearance, and overall performance. Its vertical orientation distinguishes it from other laminating machines, making it a preferred choice for various industries.

One of the primary methods employed by the Automatic Vertical Laminating Machine is heat lamination. In this process, the machine utilizes controlled heat to activate the adhesive layer, bonding it securely with the materials being laminated. This method ensures a robust and enduring union, making it ideal for applications requiring longevity and resilience.

The Automatic Vertical Laminating Machine's heat lamination process is characterized by precision. The controlled application of heat guarantees uniform adhesion, eliminating the risk of bubbles or uneven lamination. This precision is paramount in industries where flawless presentation and functionality are non-negotiable.

In scenarios where heat sensitivity is a concern, the Automatic Vertical Laminating Machine gracefully transitions to cold lamination. This method involves applying pressure-sensitive adhesive films to materials without the need for heat. The versatility of the Automatic Vertical Laminating Machine shines through in its seamless switch between heat and cold lamination, accommodating a spectrum of materials and requirements.

Cold lamination with the Automatic Vertical Laminating Machine is the epitome of delicacy. It is the go-to method for laminating materials that cannot withstand the elevated temperatures associated with heat lamination. This makes it an indispensable choice for preserving the integrity of heat-sensitive prints and substrates.

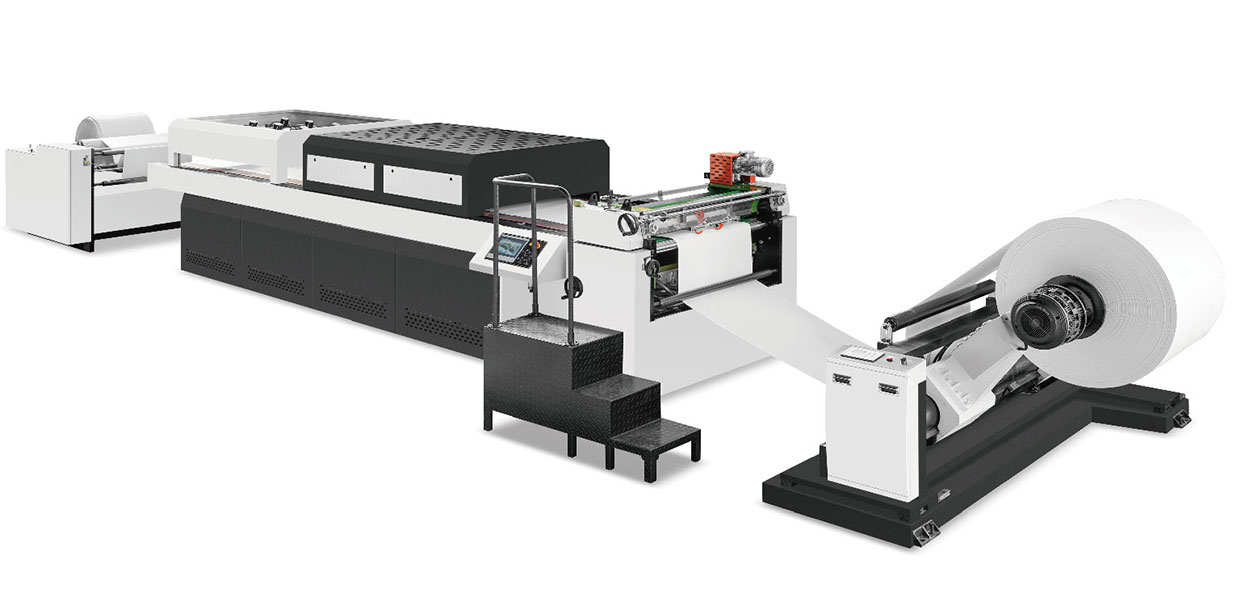

The Automatic Vertical Laminating Machine is synonymous with efficiency, and roll-to-roll lamination is a testament to its seamless operations. In this method, a continuous roll of material is fed into the machine, undergoing lamination without interruptions. This is particularly advantageous in high-volume production settings where uninterrupted workflow is paramount.

Roll-to-roll lamination with the Automatic Vertical Laminating Machine maximizes productivity by minimizing downtime. The continuous process ensures a steady output, catering to the demands of industries where time is of the essence. Whether it's large-scale printing or packaging, this method guarantees efficiency without compromising on quality.

Contrasting with the continuous nature of roll-to-roll lamination, sheet-to-sheet lamination offers a more tailored approach. This method involves laminating individual sheets, allowing for precision in handling smaller quantities. The Automatic Vertical Laminating Machine adapts seamlessly to this method, catering to the diverse needs of industries that prioritize customization.

Sheet-to-sheet lamination with the Automatic Vertical Laminating Machine is the epitome of customization. It is the preferred choice for projects where each sheet demands individual attention and unique specifications. From personalized packaging to exclusive prints, this method unlocks a realm of possibilities for businesses seeking to stand out in a competitive market.

When the elements pose a threat to the integrity of printed materials, the Automatic Vertical Laminating Machine introduces UV lamination as the ultimate protective shield. This method involves applying a UV-cured coating to the laminated surface, enhancing its resistance to abrasion, chemicals, and environmental factors.

UV lamination with the Automatic Vertical Laminating Machine extends the lifespan of laminated materials. It acts as a barrier against the detrimental effects of UV rays, ensuring that the vibrant colors and crisp details of prints remain intact over time. This makes it an invaluable choice for outdoor signage, promotional materials, and products exposed to the elements.

In the realm of printing and packaging, the Automatic Vertical Laminating Machine stands as a beacon of innovation. Its diverse laminating methods, from heat lamination to cold lamination, roll-to-roll to sheet-to-sheet, and UV lamination, offer a spectrum of possibilities for businesses aiming to elevate the quality and durability of their materials.

As industries evolve and demands for precision and customization increase, the Automatic Vertical Laminating Machine remains at the forefront, adapting to the unique needs of each project. Whether crafting resilient packaging, eye-catching prints, or durable signage, this machine continues to redefine the standards of laminating excellence. Embrace the power of the Automatic Vertical Laminating Machine and unlock a world where every layer tells a story of quality and craftsmanship.

What factors will affect the quality of Automatic pre-coating laminating machine

2021-12-03How to operate the Automatic pre-coating laminating machine correctly

2021-12-03What are the components of the automatic vertical laminating machine

2021-12-03EXPOGRÁFICA 2024 --12th-15th November Meet you in Mexico

2024-11-05Enhance Efficiency in Printing, Packaging, and Paper Processing with Jialite’s Varnishing & Laminating Machine Support

2024-11-01Optimize Production with the SG-AR1200 Automatic Roll-to-Roll UV Oil Varnish Coating Machine

2024-11-01Custom Laminating Solutions by Jialite for Tag and Cosmetic Box Manufacturers

2024-11-01

03 Dec, 2021

READ MORE

What factors will affect the quality of Automatic pre-coating laminating machine? What impact will it have? During the production process of the Automatic pre-coating laminating machine, you will find a variety of different production qualities.

03 Dec, 2021

READ MORE

How to operate the Automatic pre-coating laminating machine correctly? Which links should be paid attention to? During the operation of Automatic pre-coating laminating machine, there will be a variety of different operating procedures.

03 Dec, 2021

READ MORE

What are the components of the automatic vertical laminating machine? What is the role of each component? There will be a variety of different components in the processing of the automatic vertical laminating machine. There is no doubt about this, but each component will play a variety of different roles.

05 Nov, 2024

READ MORE

Differentiation creates value, and service moves customers; Garrett paper finishing technology makes printed matter a work of art, which is widely spread...

01 Nov, 2024

READ MORE

For the printing, packaging, and paper processing sectors, Jialite offers comprehensive installation, technical support, and operator training for varnishing and laminating machines. Our on-site services help companies in flexible packaging and corrugated carton production achieve seamless integration and maximum efficiency.

01 Nov, 2024

READ MORE

The SG-AR1200 by Jialite is an automatic roll-to-roll UV oil varnish coating machine designed for high-quality, durable coating applications. Ideal for packaging, printing, and corrugated carton manufacturing industries, this machine offers versatile oil compatibility and adjustable speeds, ensuring superior results.

01 Nov, 2024

READ MORE

Jialite offers customized laminating solutions for tag manufacturers and cosmetic box creators, enhancing production efficiency and quality. Our solutions include multi-roll laminating, double side laminating, chain knife slitting, and vibrant digital ink laminating options—ideal for the printing and packaging industries.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING