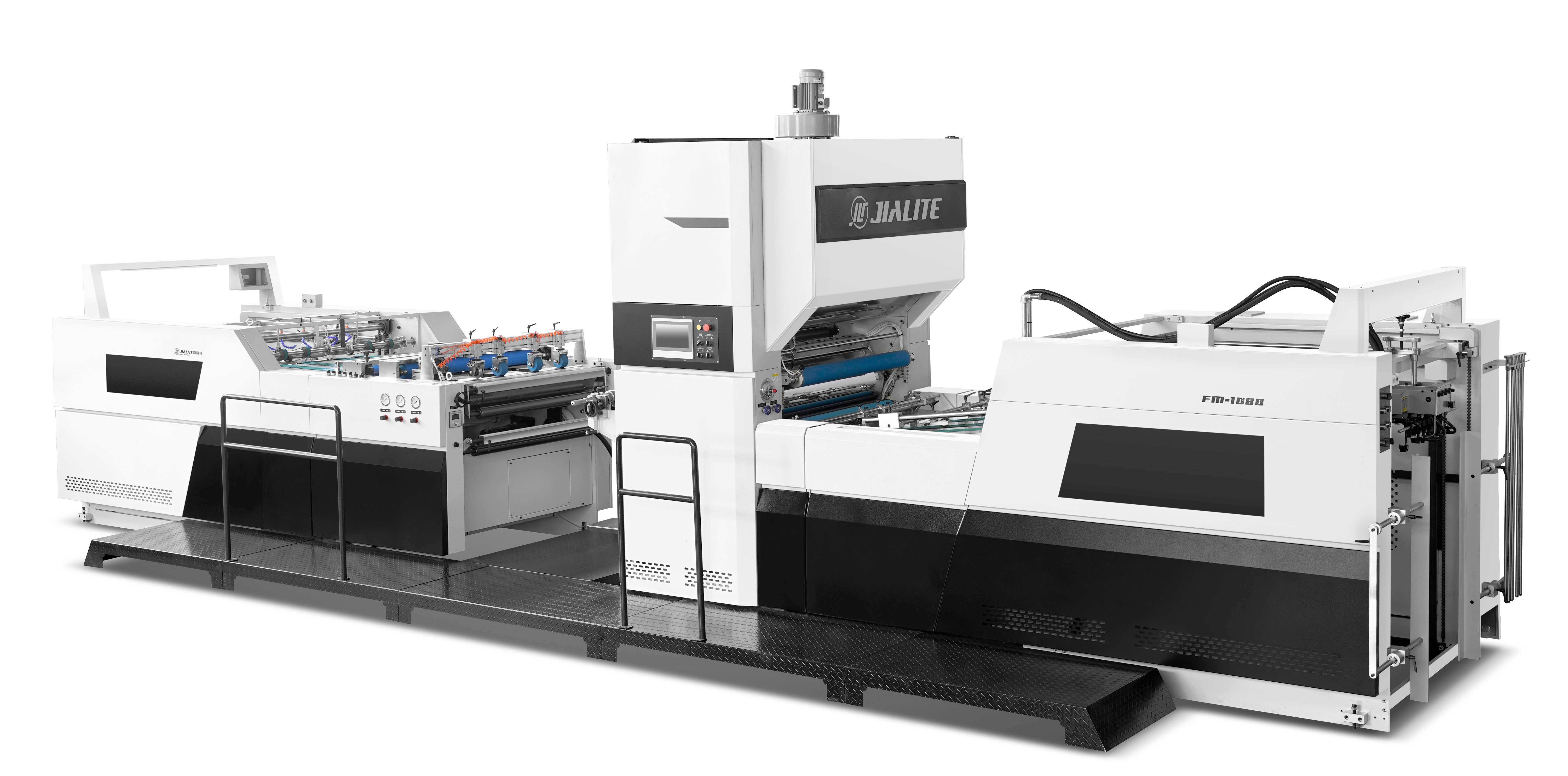

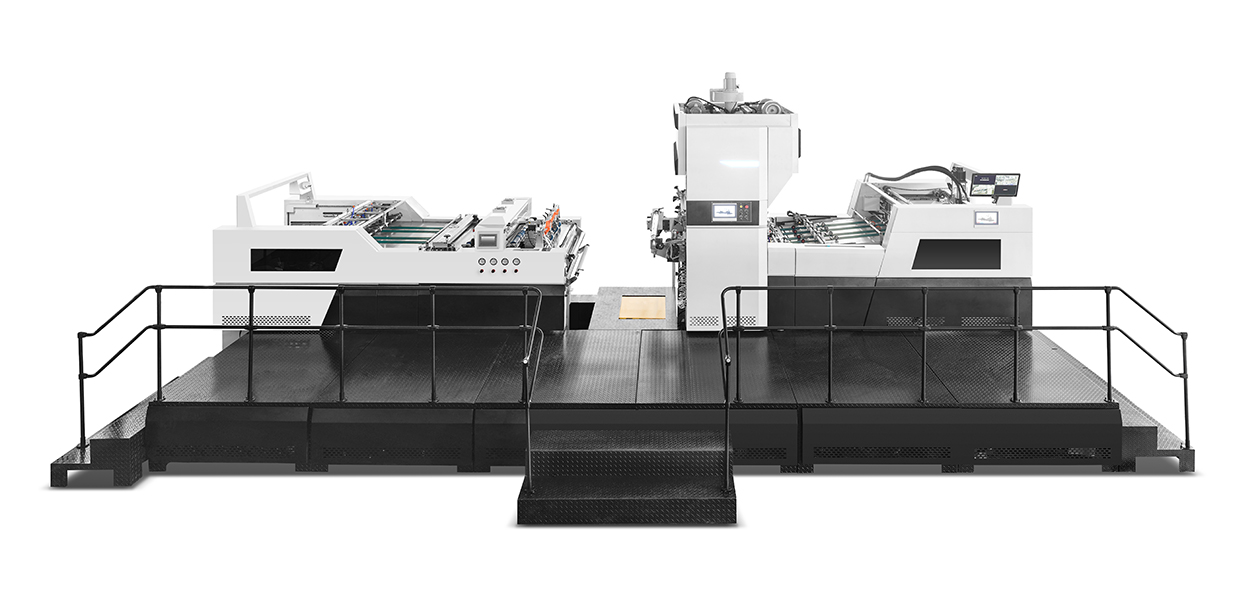

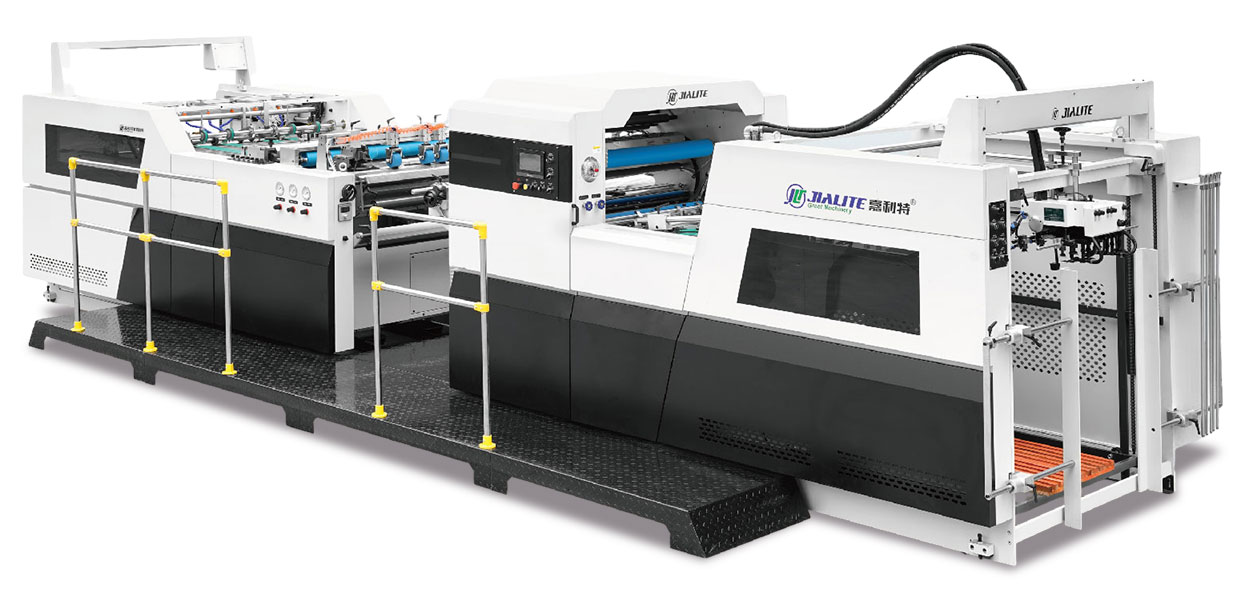

The NFM-ER series is a fully automatic, high-precision, multi-functional roll to roll laminating machine, ideal for lamination with plastic films on paper-based printed materials. Key features include:

Widely applicable across industries, this machine is suitable for lamination of:

This machine is designed to improve the durability and quality of printed materials, providing dust-proof, water-proof, and oil-proof finishes.

| Specification | NFM-ER800 | NFM-ER1080 | NFM-ER1380 |

|---|---|---|---|

| Max Paper Width | 800 mm | 1080 mm | 1380 mm |

| Min Paper Width | 300 mm | 300 mm | 300 mm |

| Max Rewinding Diameter | 1500 mm | 1500 mm | 1500 mm |

| Max Unwinding Diameter | 1500 mm | 1500 mm | 1500 mm |

| Max Rewind Load Capacity | 1200 kg | 1200 kg | 1200 kg |

| Max Unwind Load Capacity | 1200 kg | 1200 kg | 1200 kg |

| Paper Thickness | 80-600 gsm | 80-600 gsm | 80-600 gsm |

| Speed | 10-110 m/min | 10-110 m/min | 10-110 m/min |

| Film Thickness (micrometer) | 10/12/15 | 10/12/15 | 10/12/15 |

| Glue Thickness (g/m²) | 4-10 | 4-10 | 4-10 |

| Pre-gluing Film Thickness (g/m²) | 1005, 1006, 1206 (1508/1208 for embossing) | 1005, 1006, 1206 | 1005, 1006, 1206 |

| Main Motor Power | 5 kW | 5 kW | 5 kW |

| Roll Working Pressure | 15 MPa | 15 MPa | 15 MPa |

| Cable Thickness | 25 mm² | 25 mm² | 25 mm² |

| Weight | 7000 kg | 7500 kg | 8500 kg |

| Dimension (layout) | 750028003170 mm | 750030003170 mm | 750030003170 mm |

| Loading | 40 ft | 40 ft | 40 ft |

| Note | Customizable for larger sizes based on requirements |

Release Methods:

Axis Placement:

Equipped with a CCD vision sensor and rectification controller for accurate photoelectric tracking and ±75 mm travel. The system autonomously controls the tension for precise laminating alignment.

Utilizes AC vector frequency conversion, synchronized with the unwinding system. The paper roll is hydraulically controlled for smooth and even rewinding. Includes torque adjustment and an air expansion shaft for efficient winding.

What types of films does the machine support?

Is this machine suitable for high-volume lamination?

Can it handle thicker paper types?

Does it include a temperature control system?

How does the machine ensure accurate alignment?

A thermal laminator activates adhesive with heat, providing a stronger bond than regular laminators, which may use pressure-sensitive adhesives.

The NFM-ER series automatic roll to roll laminator offers competitive pricing and advanced features, making it a cost-effective choice for businesses.

Self-adhesive laminating relies on pressure-sensitive adhesive, while thermal laminating uses heat-activated adhesives for greater durability.

The NFM-ER series uses an electromagnetic heating system, which heats up quickly for efficient operation.

| No. | Name | Brand | Origin |

|---|---|---|---|

| 1 | Main motor | Bolilai | Jiangsu, China |

| 2 | Vacuum pump | Tongyou | Jiangsu, China |

| 3 | Bearing | NSK | Japan |

| 4 | Frequency converter | Delta | Taiwan |

| 5 | Green flat button | Schneider | France |

| 6 | Red flat button | Schneider | France |

| 7 | Emergency stop button | Schneider | France |

| 8 | Rotary knob | Schneider | France |

| 9 | AC contactor | Schneider | France |

| 10 | Servo motor | Weikeda | Shenzhen, China |

| 11 | Servo driver | Weikeda | Shenzhen, China |

| 12 | Servo reduction gear | Taiyi | Shanghai, China |

| 13 | Switch power | Delta | Taiwan |

| 14 | Temperature module | Delta | Taiwan |

| 15 | Programmable logic controller | Delta | Taiwan |

| 16 | Brake resistance | Delta | Taiwan |

| 17 | Cylinder | AIRTAC | Shanghai, China |

| 18 | Electromagnetic valve | AIRTAC | Shanghai, China |

| 19 | Touch screen | Xiankong | Shenzhen, China |

| 20 | Breaker | CHNT | Wenzhou, China |

| 21 | Hydraulic pump | Tiandi Hydraulic | Ningbo, China |

| 22 | Chain | KMC | Hangzhou, China |

| 23 | One-way pneumatic diaphragm pump | FAZER | Wenzhou, China |

| 24 | Draught fan | Yinniu | Taizhou, China |

| 25 | Encoder | Omron | Japan |

| 26 | Rolling motor | Shanghe | Shanghai, China |

China Manufacturer of High Speed Automatic Thermal Laminating Machine

2024-09-30NFY-A HIGH SPEED AUTOMATIC THERMAL LAMINATING MACHINE IN CHINA

2024-09-29China Automatic Laminating Machine NFY-A HIGH SPEED AUTOMATIC THERMAL

2024-09-29HIGH SPEED AUTOMATIC VERTICAL LAMINATING MACHINE NFM-E1080 WITH

2024-09-29

30 Sep, 2024

READ MORE

The NFY-B1080 high speed automatic thermal laminating machine is designed for precise laminating operations, offering high-speed performance for packaging and printing applications. It handles various films including OPP, BOPP, PET, and SOFT TOUCH FILM, ensuring enhanced product durability with dust-proof, water-proof, and oil-proof features.

29 Sep, 2024

READ MORE

The NFY-A800 high speed automatic thermal laminating machine offers advanced laminating capabilities for both small and large-scale lamination. Featuring precise servo control and electromagnetic heating, it is designed to enhance lamination quality in advertising, packaging, books, and magazines. The machine provides effective solutions for dust-proof, water-proof, and oil-proof lamination in the printing and packaging industries.

29 Sep, 2024

READ MORE

The NFY-A800 high speed automatic thermal laminating machine provides efficient lamination solutions for the printing and packaging industries. It supports both water-based and thermal lamination, handling OPP, BOPP, and PET films with high accuracy. The machine features servo-controlled feeding, electromagnetic heating, and customizable settings for high-speed operations.

29 Sep, 2024

READ MORE

The NFM-E1080 high speed automatic vertical laminating machine is equipped with advanced features such as a hot knife, window unit, and electromagnetic heating system. It supports water-based and thermal lamination, handling films like BOPP, OPP, PET, and metallic films. The machine provides reliable and efficient lamination for packaging and printing industries, making it an excellent choice for high-demand applications.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING