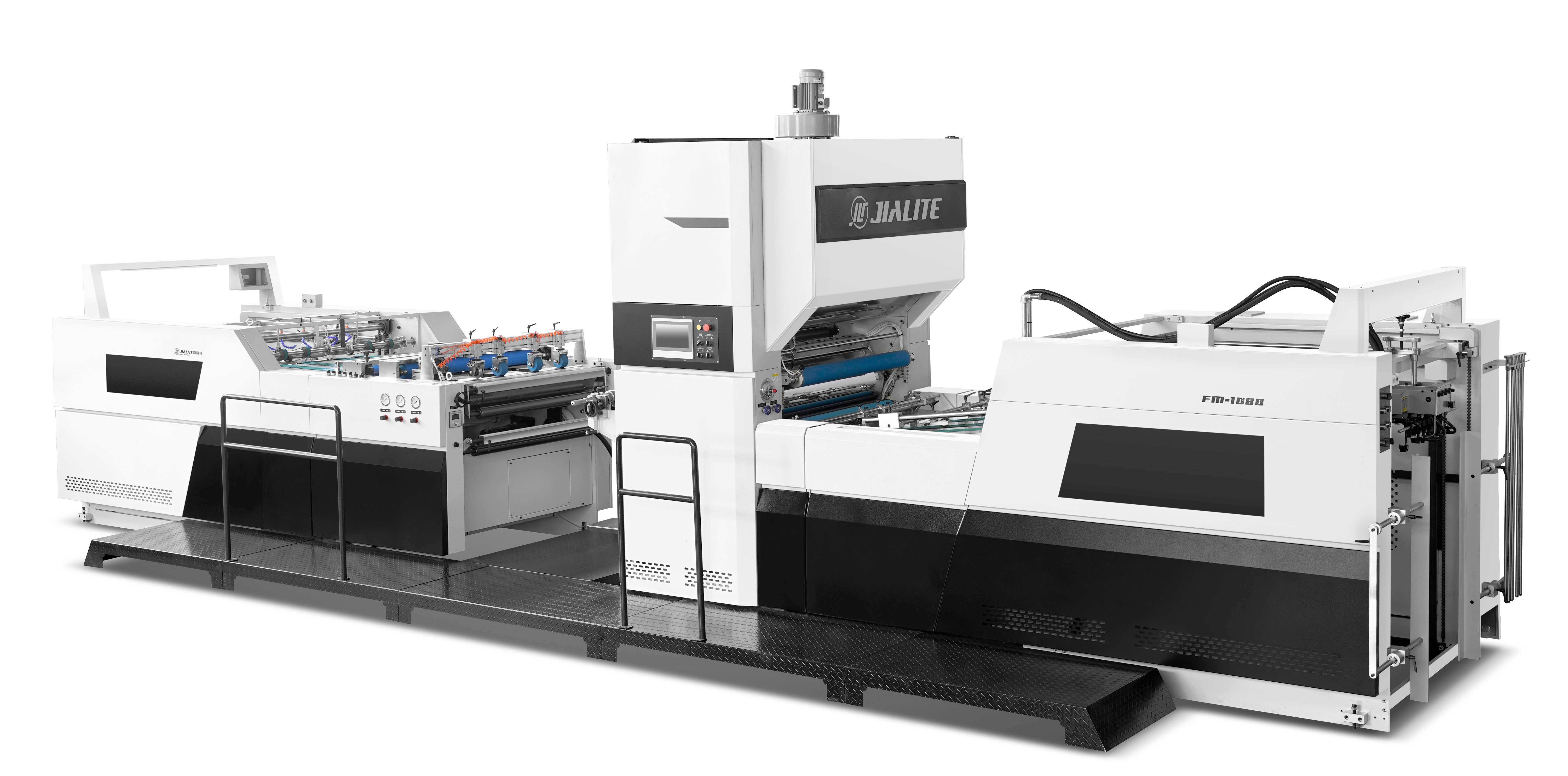

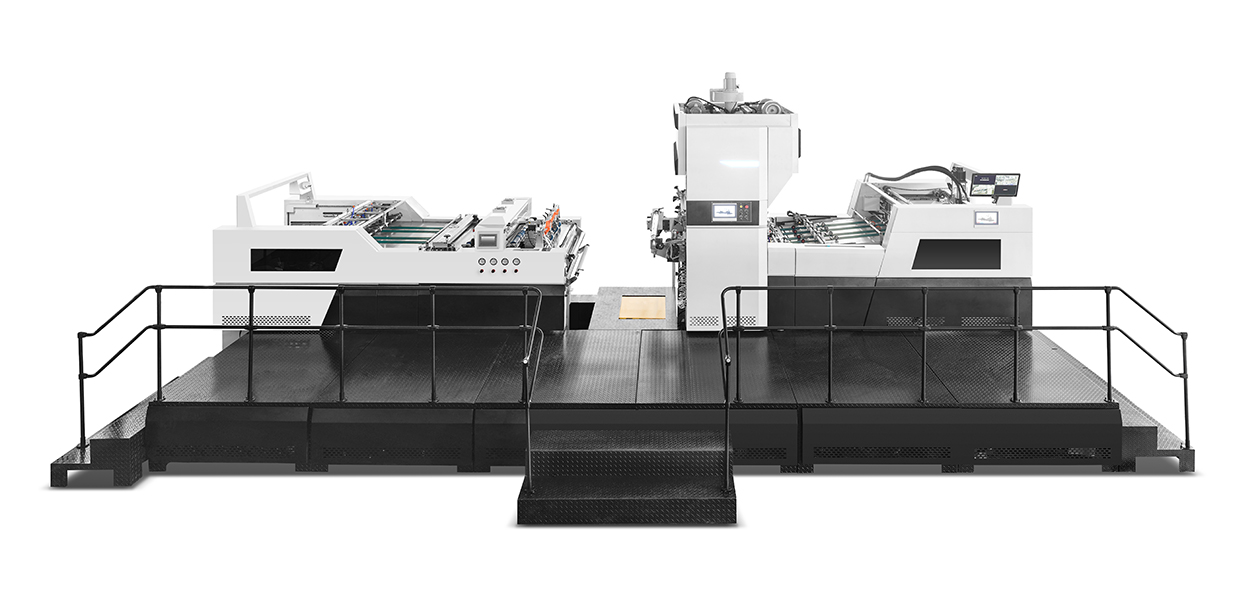

In the fast-paced world of industrial manufacturing, the demand for efficient and reliable machinery has never been higher. One such marvel that has revolutionized the laminating process is the Automatic Vertical Laminating Machine. In this extensive exploration, we will delve into the various components that make up this cutting-edge device, shedding light on its intricate design and highlighting the crucial role it plays in enhancing productivity and quality in the laminating industry.

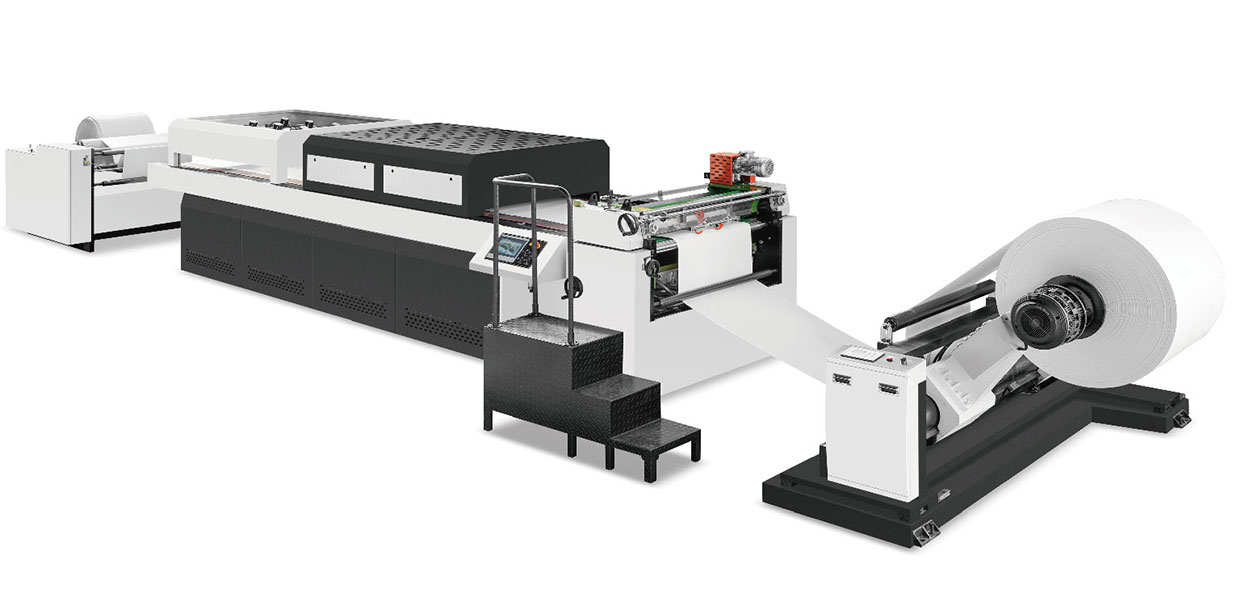

At the heart of the Automatic Vertical Laminating Machine lies its core mechanism, a sophisticated arrangement of gears, rollers, and precision-engineered components. This intricate system ensures seamless operation, allowing for precise control over the laminating process. As materials pass through the machine, the Automatic Vertical Laminating Machine orchestrates a symphony of movements, resulting in flawlessly laminated products.

Driving the entire operation is the robust Automatic Vertical Laminating Machine engine. This powerhouse is meticulously designed to provide the necessary torque and speed for optimal laminating performance. Its efficiency is a testament to the relentless pursuit of excellence in industrial machinery.

To harness the full potential of the Automatic Vertical Laminating Machine, operators rely on an intuitive and user-friendly control panel. This interface serves as the command center, allowing users to customize settings, monitor progress, and troubleshoot with ease. The incorporation of advanced technology in the control panel ensures that even novices can operate the machine with confidence.

Temperature Control: The Automatic Vertical Laminating Machine's control panel boasts precise temperature control, a crucial factor in achieving optimal lamination results. Operators can fine-tune the temperature settings to accommodate different types of laminating materials.

Speed Adjustment: Flexibility is key in industrial settings. The ability to adjust laminating speed ensures compatibility with various materials and production requirements. The Automatic Vertical Laminating Machine excels in providing this adaptability through its user-friendly speed adjustment feature.

A defining feature of the Automatic Vertical Laminating Machine is its intricate roller system. Comprising multiple rollers with specialized functions, this component plays a pivotal role in ensuring uniform lamination and preventing defects. Let's take a closer look at the ballet of rollers within the Automatic Vertical Laminating Machine.

As materials enter the Automatic Vertical Laminating Machine, infeed rollers take center stage. Their primary function is to guide materials with precision, ensuring a smooth and even flow through the laminating process. The meticulous engineering of these rollers minimizes the risk of misalignment, a common concern in laminating operations.

At the core of the laminating process are the specialized laminating rollers. These rollers apply controlled pressure and heat, facilitating the bonding of laminating films to substrates. The Automatic Vertical Laminating Machine excels in this aspect, with meticulously designed laminating rollers that guarantee impeccable bonding without compromising material integrity.

The journey concludes with the outfeed rollers, responsible for safely delivering the laminated product. Their strategic placement ensures that the final output maintains its integrity and quality. The Automatic Vertical Laminating Machine's outfeed rollers epitomize the commitment to delivering flawlessly laminated materials to the next stage of the production process.

Central to the success of the Automatic Vertical Laminating Machine is its advanced heating system. This component is engineered to perfection, providing consistent and precise heat application throughout the laminating process. The result is a uniform and durable bond between laminating films and substrates.

Unlike conventional laminating machines, the Automatic Vertical Laminating Machine boasts unparalleled temperature uniformity. This is achieved through innovative heating elements and thermal control mechanisms. The ability to maintain consistent temperatures across the entire laminating width sets this machine apart in terms of quality and reliability.

In any industrial setting, prioritizing safety is paramount. The Automatic Vertical Laminating Machine is equipped with a range of safety features designed to safeguard operators and minimize the risk of accidents.

Should an unforeseen situation arise, the Automatic Vertical Laminating Machine's emergency stop mechanism provides an instantaneous halt to all operations. This ensures the safety of operators and prevents potential damage to the machine or materials.

The Automatic Vertical Laminating Machine is equipped with intelligent overheat protection. This feature detects abnormal temperature spikes and takes proactive measures to prevent overheating. By preserving the machine's integrity, this safety feature extends its lifespan and enhances overall reliability.

To maintain peak performance, the Automatic Vertical Laminating Machine is designed with user-friendly maintenance and troubleshooting features. This ensures that operators can address issues swiftly, minimizing downtime and maximizing productivity.

The Automatic Vertical Laminating Machine's self-diagnostic system is a game-changer in the realm of industrial machinery. By proactively identifying potential issues, operators can address them before they escalate, reducing the need for extensive repairs and costly downtime.

Efficient maintenance is facilitated by easy access to critical components. The Automatic Vertical Laminating Machine is engineered with this principle in mind, allowing operators to perform routine maintenance tasks with minimal effort. This user-centric approach contributes to the longevity and reliability of the machine.

As technology continues to evolve, the landscape of industrial machinery undergoes constant transformation. The Automatic Vertical Laminating Machine is no exception, and industry experts predict exciting developments in the near future.

The convergence of industrial machinery with smart manufacturing principles is on the horizon for the Automatic Vertical Laminating Machine. Integration with IoT (Internet of Things) technology is expected to enhance connectivity, enabling real-time monitoring and control for optimized laminating processes.

In response to growing environmental concerns, manufacturers are exploring eco-friendly innovations for the Automatic Vertical Laminating Machine. This includes the development of sustainable materials and energy-efficient components, aligning the laminating industry with global sustainability goals.

In conclusion, the Automatic Vertical Laminating Machine stands as a testament to human ingenuity and technological advancement in the realm of industrial machinery. From its core mechanism to the intricacies of the control panel, rollers, heating system, and safety features, every component is a meticulously crafted piece of the laminating puzzle. As we look toward the future, the Automatic Vertical Laminating Machine is poised to continue its journey of innovation, shaping the landscape of laminating technology for years to come.

What are the main structures of Automatic pre-coating laminating machine

2021-12-03What factors will affect the quality of Automatic pre-coating laminating machine

2021-12-03How to operate the Automatic pre-coating laminating machine correctly

2021-12-03EXPOGRÁFICA 2024 --12th-15th November Meet you in Mexico

2024-11-05Enhance Efficiency in Printing, Packaging, and Paper Processing with Jialite’s Varnishing & Laminating Machine Support

2024-11-01Optimize Production with the SG-AR1200 Automatic Roll-to-Roll UV Oil Varnish Coating Machine

2024-11-01

03 Dec, 2021

READ MORE

What are the main structures of Automatic pre-coating laminating machine? How is the product? The Automatic pre-coating laminating machine product is a special equipment that combines various printed materials and related films. This equipment can be processed and decorated, and can be automatically input during the printing process.

03 Dec, 2021

READ MORE

What factors will affect the quality of Automatic pre-coating laminating machine? What impact will it have? During the production process of the Automatic pre-coating laminating machine, you will find a variety of different production qualities.

03 Dec, 2021

READ MORE

How to operate the Automatic pre-coating laminating machine correctly? Which links should be paid attention to? During the operation of Automatic pre-coating laminating machine, there will be a variety of different operating procedures.

05 Nov, 2024

READ MORE

Differentiation creates value, and service moves customers; Garrett paper finishing technology makes printed matter a work of art, which is widely spread...

01 Nov, 2024

READ MORE

For the printing, packaging, and paper processing sectors, Jialite offers comprehensive installation, technical support, and operator training for varnishing and laminating machines. Our on-site services help companies in flexible packaging and corrugated carton production achieve seamless integration and maximum efficiency.

01 Nov, 2024

READ MORE

The SG-AR1200 by Jialite is an automatic roll-to-roll UV oil varnish coating machine designed for high-quality, durable coating applications. Ideal for packaging, printing, and corrugated carton manufacturing industries, this machine offers versatile oil compatibility and adjustable speeds, ensuring superior results.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING