Maintenance method of Cold Laminator Machine

Regular cleaning of the cold laminator machine will ensure its longevity. The following is a guide on how to properly maintain your machine:

1. Turn off the power and unplug the machine.

2. Clean the laminating rollers with a damp cloth. Be careful not to get water on the electrical components of the machine.

3. Wipe down the exterior of the machine with a dry cloth.

4. Once a month, use a vacuum cleaner with a soft brush attachment to clean the interior of the machine. Be careful not to damage any of the internal components.

5. If you notice any problems with your cold laminator machine, such as uneven lamination or poor quality output, take it to a professional for service or repairs.

It is important to keep your cold laminator machine well-maintained in order to prolong its lifespan and prevent any unnecessary repairs. Here are some tips on how to do just that:

Keep the machine clean – one of the most important aspects of machine maintenance is keeping it clean. Dust and dirt can build up over time and cause damage to the sensitive parts of the machine. Be sure to wipe down the exterior and interior of the machine on a regular basis with a soft, dry cloth.

Lubricate moving parts – another key part of maintaining your cold laminator machine is to lubricate all moving parts. This will help keep them running smoothly and prevent any wear and tear. Be sure to use a high-quality lubricant specifically designed for use on laminating machines.

Check for wear and tear – regularly check your cold laminator machine for any signs of wear and tear. If you notice any damage, be sure to have it repaired as soon as possible by a qualified technician. Ignoring small problems can often lead to larger, more expensive repairs down the road.

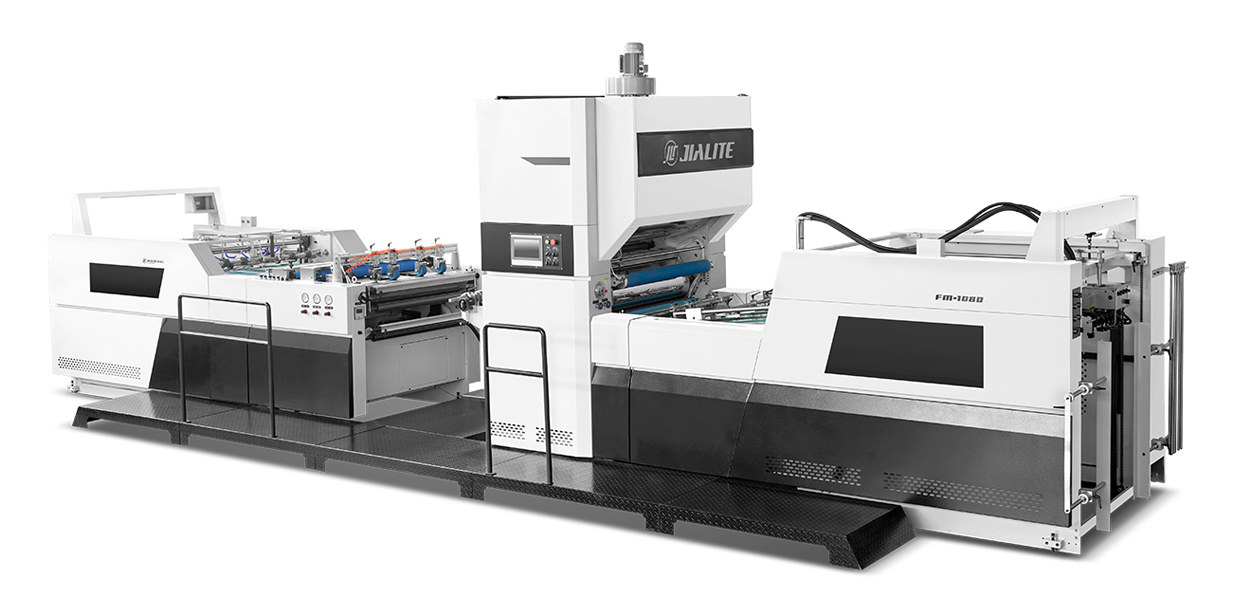

Advantages and Features of Cold Laminator Machine

A laminating machine is a versatile tool that can be used in a number of settings, from schools and offices to homes and small businesses. Laminating machines use heat and pressure to seal documents and images inside plastic film, which protects the material from wear and tear, moisture damage, and fading.

There are two types of laminating machines: hot laminators and cold laminators. Hot laminators use heat to seal the laminate to the document, while cold laminators use adhesive. Cold laminating is often the preferred method for delicate materials such as photos because there is no risk of heat damage.

Here are some of the advantages of using a cold laminator:

- Cold lamination prevents heat damage to delicate materials.

- Cold lamination does not require a power source, making it more portable than hot lamination.

- Cold laminate is less likely to peel or warp over time than hot laminate.

- Cold laminate can be applied to curved surfaces without bubbling or wrinkling.

Cold lamination is a process that applies an adhesive film to the surface of a document. The film is then sealed to the document using pressure and cold. Cold lamination is less likely to damage sensitive documents than hot lamination. Cold lamination also does not require the use of a roller, so it is less likely to leave wrinkles or bubbles in the laminated document.

A cold laminator machine is a versatile tool that can be used for a variety of projects, both big and small. Here are just a few of the advantages and features that make cold laminating an attractive option for businesses and individuals:

-Cold laminating protects your documents from tearing, fading, and water damage.

-It can be used on a variety of materials, including paper, fabric, photos, and more.

-Laminating is quick and easy, and doesn’t require any special skills or training.

-A cold laminator machine is relatively inexpensive, and easy to find at most office supply stores.

So if you’re looking for a way to protect your documents and extend their lifespan, cold laminating is definitely worth considering.