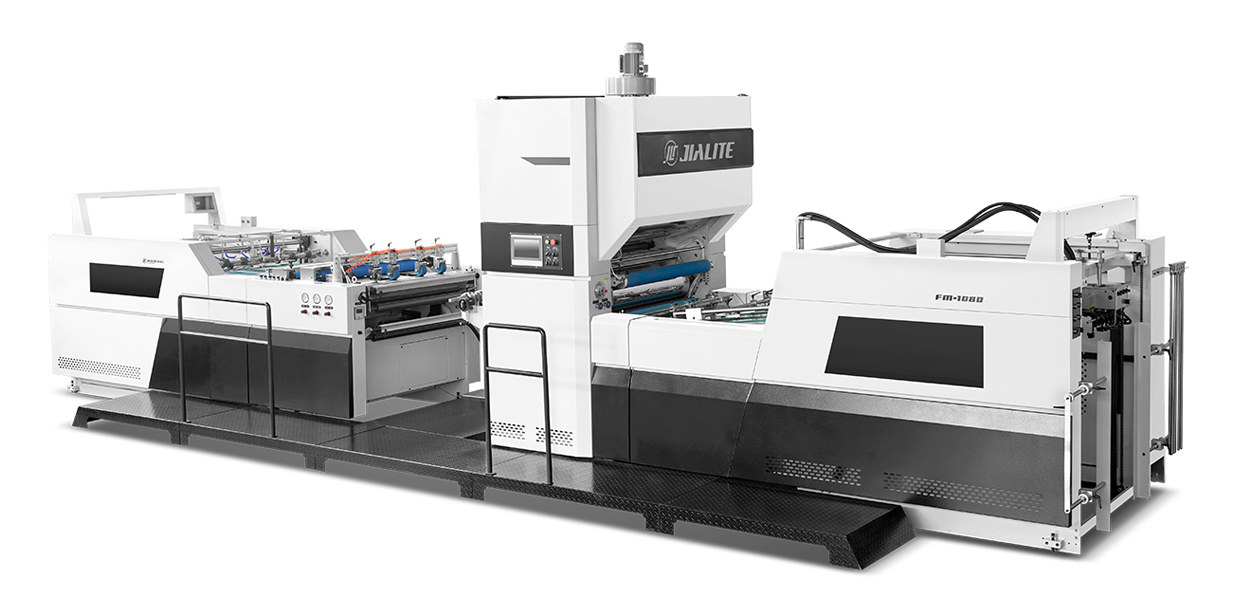

How the Roll Laminator Machine works

Invented in the 1950s, laminating machines are now an essential piece of equipment for anyone who needs to protect or preserve documents, photos, or other materials. But how does a roll laminator work?

A roll laminator machine consists of two heated rollers that melt adhesive as it passes through. The adhesive bonds to the material being laminated as it cools and hardens.

Roll laminators come in a variety of sizes, but they all operate in essentially the same way. The document or material to be laminated is placed on a carrier sheet, which is then fed into the machine. As the carrier sheet passes through the rollers, the adhesive is melted and evenly applied to the document or material.Once the document or material exits the rollers, it is cooled and then trimmed to size. The result is a laminated document or material that is protected from moisture, dirt, and other contaminants.

The roll laminator machine is a versatile, easy-to-use device that can be used to protect documents and extend their lifespan. Here's a look at how the roll laminator machine works:

1. The roll laminator machine has two heated rollers that are encased in plastic.

2. When the machine is turned on, the rollers heat up to a predetermined temperature.

3. A sheet of laminate film is fed into the machine.

4. As the laminate film passes through the rollers, it is heated and stretched.

5. The laminate film is then cooled and shrunk to fit snugly around the document.

Laminating Questions and Tips

why is my scotch laminator wrinkling

The roll laminator machine is a very versatile piece of equipment that can be used for a variety of purposes. There are many different types of machines on the market, but they all work in basically the same way.