A vinyl lamination machine is a helpful tool used to apply a protective and glossy layer to vinyl materials such as stickers, signs, and images. This machine is designed with a heated roller that melts the adhesive on the lamination film and then applies that film onto the vinyl item. Through this process, the vinyl material becomes stronger and more durable, and the lamination film helps to protect it from scratches, fading, and other types of damage. This machine is very easy to use and can be a great addition to any business or craft room. Laminating with a vinyl lamination machine not only protects your materials, but it also gives them a sleek and professional look.

A vinyl lamination machine is a helpful tool that adds a protective layer over printed materials or images to prolong their lifespan. The machine is simple to operate and works by taking a printed item and feeding it through the machine which then applies a clear, thin layer of plastic film over the top of the item. This high-quality layer helps to protect against wear and tear caused by handling and harsh environmental conditions. The result? Your items will withstand the test of time, holding up to repeated use, frequent handling, or harsh environmental influences. Overall, a vinyl lamination machine is a fantastic investment that will ensure your printed materials look their best for years to come!

Vinyl lamination machines are essential tools used in the printing industry to enhance the quality and durability of printed materials. The principle behind the operation of a vinyl lamination machine is quite simple - it involves the application of a thin protective film onto the surface of the printed material. This film, which is made of high-quality vinyl material, provides a layer of protection against scratches, water damage, and fading.

Vinyl lamination machines work by using heat and pressure to apply the protective film onto the printed material. The printed material is first fed into the machine, where it is carefully positioned for lamination. The vinyl film is then fed into the machine and brought into contact with the printed material.

Once the two materials are in contact, the machine applies heat and pressure to activate the adhesive properties of the vinyl film. This process causes the vinyl film to bond firmly with the printed material, creating a seamless, protective layer over the printed material.

Overall, vinyl lamination machines offer an effective and efficient solution for enhancing the quality and lifespan of printed materials. They are widely used in various industries, ranging from commercial printing to signage production, and have become an indispensable tool in the world of print production.

Purchasing a vinyl lamination machine is a great investment for individuals and businesses that require high-quality laminated materials. The cost of a vinyl lamination machine typically ranges from $100 to $3,000, depending on the size, capacity, and features of the machine. While the upfront cost may seem daunting, the long-term benefits of owning a vinyl lamination machine outweigh the price. For example, businesses can increase their profitability by bringing laminating services in-house, rather than outsourcing to a third-party. Additionally, individuals can enjoy the convenience of creating laminated materials at home without the need to constantly visit a print or copy shop. Overall, purchasing a vinyl lamination machine is an excellent choice for anyone looking to create high-quality laminated materials while saving time and money.

When looking for a thermal lamination machine, there are many factors to consider. Of course, one of the most important things to think about is the price. Luckily, there are many affordable options available on the market.

Thermal lamination machine prices vary depending on a number of factors. Some machines are more expensive than others because they are designed for higher-volume laminating, or they offer additional features such as adjustable temperature settings or automatic shutoff.

However, there are also many affordable thermal lamination machines that can provide high-quality results. These machines are often smaller and more straightforward, but they can still handle most common laminating tasks.

When looking at pricing, keep in mind that the cost of the machine is just one factor. You will also need to purchase lamination sheets or pouches, which can add to the overall cost. Additionally, some machines may require maintenance or repair over time, which can also be an additional expense.

Overall, it is important to choose a thermal lamination machine that fits both your budget and your needs. By doing research and comparing prices, you can find the perfect machine at a price that you can afford.

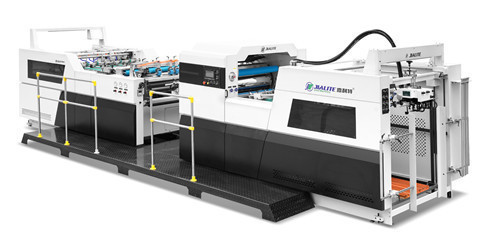

GREAT since from 1995. Continuous introduction the European concept of equipment manufacturing, based on more than 20 years experience, we focus on the development and innovation of laminating machine and UV coating machine, GREAT provide efficiency products and reasonable post press solution to every user.

Company structure is scientific and reasonable with humanized management mechanism. The ERP management system and 5S standard are used to ensure the strict system of development,procurement, processing, production and assembly, factory inspection, packaging and logistics.Mature customer service system, the domestic First-tier and second-tier cities have direct selling and service branch, technical engineers team at any time provide after-sale consultation and arrangement installation and troubleshooting service for foreign customers.

Daily maintenance of coating machine

2022-02-24Care and maintenance of coating machine

2022-02-21Application field of automatic coating machine

2022-01-21How to choose Automatic coating machine manufacturers

2022-01-1824 Feb, 2022

READ MORE

The transmission and moving parts of the newly installed coating machine must be inspected, tightened, refueled and maintained within a week of use; after that, regular inspection and maintenance must be carried out every month.

21 Feb, 2022

READ MORE

Ensure that the coating equipment is installed horizontally. It should be grounded, and an independent leakage switch should be installed for safe use.

21 Jan, 2022

READ MORE

Liquid ink manufacturing for testing ink shade/strength and coatings.

18 Jan, 2022

READ MORE

Due to the lack of in-depth understanding, most friends do not know which part of Automatic coating machine manufacturers to choose to obtain satisfactory results. In fact, as long as we have the patience to explore more things, we will soon know that manufacturers that have been established for many years, while focusing on the industry, have cooperated with different customers, and they will definitely have strong strength.

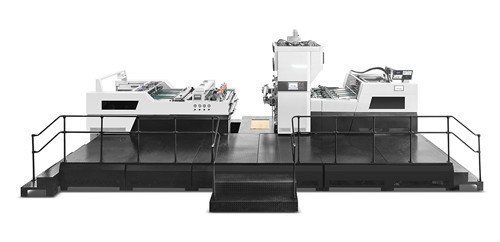

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING