An industrial laminator is a specialized machine designed to apply a protective layer or coating to various materials. This process, known as lamination, involves bonding layers of material together using heat, pressure, or adhesives. The industrial laminator ensures a strong and durable bond, significantly improving the material's properties and performance.

Industrial laminators come in various types, catering to different industries and materials. The primary types include:

1. Roll Laminators

Roll laminators are versatile and widely used for large-scale projects. They utilize rolls of laminate film to cover materials uniformly. Roll laminators are popular in industries like printing, packaging, and signage manufacturing.

2. Pouch Laminators

Pouch laminators are compact and suitable for smaller-scale lamination. They use pre-sealed laminating pouches to encase documents, photos, or cards. Pouch laminators are commonly found in offices, schools, and retail environments.

3. Hot and Cold Laminators

Hot laminators apply heat during the lamination process, making them ideal for materials sensitive to pressure. Cold laminators, on the other hand, use pressure without heat, suitable for temperature-sensitive materials like photographs.

1 Packaging Industry

In the packaging industry, industrial laminators play a crucial role in enhancing product protection and shelf appeal. Laminated packaging materials provide resistance against moisture, UV rays, and other environmental factors, preserving the quality of the packaged goods.

2 Automotive Sector

Industrial laminators are instrumental in manufacturing automotive parts like dashboards, door panels, and interior trims. Laminated components offer improved aesthetics and resistance to wear and tear, ensuring longevity.

3 Electronics Manufacturing

Electronics manufacturers use industrial laminators to protect sensitive circuit boards and electronic components from dust, moisture, and mechanical damage. Laminated circuit boards exhibit better performance and reliability.

4 Construction Materials

Industrial laminators are employed in the construction industry to laminate materials like glass, wood, and metal. Laminated construction materials gain added strength and resistance to harsh weather conditions.

1 Enhanced Durability

Lamination significantly increases the durability of materials, making them resistant to scratches, tears, and fading. This durability extends the lifespan of products, reducing the need for frequent replacements.

2 Improved Aesthetic Appeal

Laminated materials often boast a polished and professional appearance. Manufacturers can choose from a wide range of finishes, textures, and colors to enhance the visual appeal of their products.

3 Moisture and Heat Resistance

Lamination creates a protective barrier, rendering materials resistant to moisture, heat, and other environmental factors. This feature is particularly valuable in industries dealing with extreme conditions.

4 Cost-Effectiveness

Investing in industrial laminators proves cost-effective in the long run, as it reduces material wastage and maintenance costs. Additionally, the extended lifespan of laminated products contributes to overall savings.

1 Consideration Factors

Selecting the appropriate industrial laminator depends on factors like the type of material, intended use, and production volume. It is essential to assess the laminator's capacity, speed, and compatibility with the materials in question.

2 Maintenance and Safety

Regular maintenance is vital to ensure optimal performance and longevity of the laminator. Furthermore, adherence to safety guidelines while operating the machine is crucial to prevent accidents and maintain a secure working environment.

Industrial laminators streamline manufacturing processes by expediting lamination and improving the quality of end products. The efficiency gained through lamination positively impacts production timelines and reduces material wastage.

Advancements in technology have led to the development of high-speed, automated industrial laminators with improved precision and customization options. These innovations enable manufacturers to meet diverse customer demands efficiently.

The industrial laminator market is expected to witness significant growth in the coming years. As industries seek ways to enhance product durability and visual appeal, the demand for efficient and advanced laminating solutions will rise.

GREAT since from 1995. Continuous introduction the European concept of equipment manufacturing, based on more than 20 years experience, we focus on the development and innovation of laminating machine and UV coating machine, GREAT provide efficiency products and reasonable post press solution to every user.

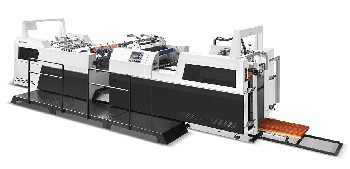

NFY-B1080 Automatic Thermal Laminating Machine

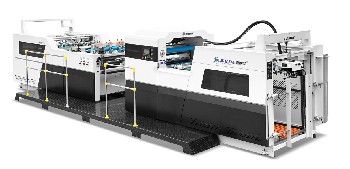

NFY-A800 High Speed Automatic Economic Thermal Laminating Machine

CORRUGATED COLOR BOX

2021-02-24HAND PAPER BAG

2021-02-24CARD, HANGTAG, CALENDAR

2021-02-24FOOD AND BAKING PACKAGING BOX

2021-02-24Walking into Shandong, approach users | Season 1

2023-06-1524 Feb, 2021

READ MORE

Many products now have packaging boxes. Whether the packaging box is high-end is directly related to the grade of the product. At the same time, the pattern printing on the packaging box is also exquisite. If the printing effect is good, it can increase the sense of design and it can also increase the grade of the product. But for the sake of environmental protection, the current packaging boxes use corrugated color boxes. Let's look at the application of printing and packaging machines in corrugated color boxes:

24 Feb, 2021

READ MORE

Handbags are already an indispensable packaging bag for many stores when selling products. If this kind of packaging bag is designed well, it can improve the grade of the product and also show the characteristics of the product. Therefore, the outside of the handbag is printed with fonts and performance. The designer is very necessary, let’s take a look at what are the benefits of the printing and packaging machine in the application of portable paper bags?

24 Feb, 2021

READ MORE

24 Feb, 2021

READ MORE

Baked foods are sold in hard packaging boxes, and environmentally safe packaging boxes are also required. After all, they are products that need to be eaten. If the packaging is not environmentally friendly, the packaging will contaminate the food, so choose a printing packaging machine It is very critical, so the application of printing and packaging machines in food baking packaging boxes should be considered from the following aspects:

15 Jun, 2023

READ MORE

Differentiation creates value, and service moves customers; Garrett paper finishing technology makes printed matter a work of art, which is widely spread...

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING